In chemical processing plants, safety valves are the first line of defense against overpressure incidents in pipelines, reactors, and storage systems. Their role in preventing catastrophic failures, ensuring operational continuity, and safeguarding personnel and the environment cannot be overstated. This case study highlights how [Your Company Name]’s safety valves successfully addressed critical challenges in a real-world chemical pipeline application, including corrosive media, thermal cycling, and strict regulatory compliance.

Case Background

A leading European chemical manufacturer faced recurring issues with pipeline overpressure in a facility handling highly corrosive ethylene oxide (ETO) and propylene operations.

The existing valves struggled with:

Corrosive Media: Frequent leaks and accelerated wear due to exposure to acidic byproducts and halide ions.

Thermal Cycling: Extreme temperature fluctuations (ranging from -40°C to 250°C) caused structural stress and reduced seal integrity.

Solution Implementation

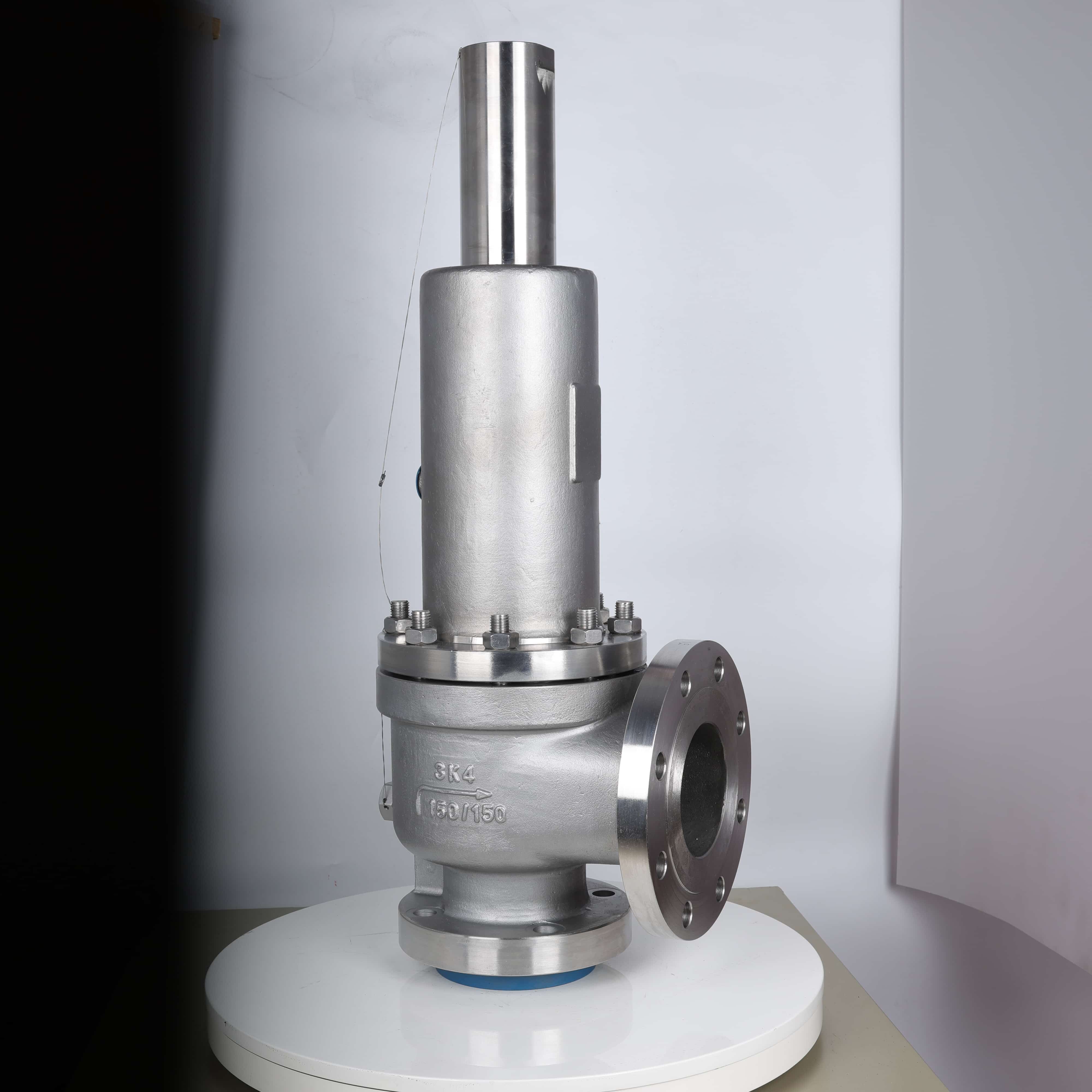

We deployed a tailored solution combining advanced materials and precision engineering:

1. Material Innovation for Corrosion Resistance

Valve Body: Constructed from Hastelloy C-276, a nickel-molybdenum alloy proven to withstand aggressive chemicals like ETO and chloride-laden media.

Seal Components: Utilized perfluoroelastomer (FFKM) seats and Monel 400 springs, which maintained integrity in pH 1 environments for over 18 months without pitting.

Coatings: Applied a tungsten carbide electroplated layer on the valve stem to prevent crevice corrosion and galvanic damage.

2. Thermal Cycling Resilience

Dynamic Seal Design: compensating for thermal expansion and contraction while reducing stem wear.

Stem Geometry: Optimized the stem’s cross-section to minimize stress concentration during temperature shifts, aligning with API 520 Class I standards.

3. Compliance and Predictive Maintenance

Certifications: The valves were rigorously tested to meet ASME BPVC Section VIII Div. 1 (pressure vessel safety) and PED Annex IV (EU market compliance) standards, including fire-safe and fugitive emission tests.

Results

Safety: Eliminated catastrophic failure risks, achieving zero process-related incidents over three years of operation.

Compliance: Passed ASME and PED audits, enabling seamless market access across North America and Europe.