Introduction

Back pressure is a fundamental concept in fluid mechanics and industrial engineering, playing a critical role in the stability, safety, and efficiency of fluid transport and processing systems. From chemical reactors to water treatment plants, and from power generation boilers to oil pipelines, the control and utilization of back pressure directly impact the performance of core equipment—especially valves. This article systematically explains the definition, generation mechanism, and application principles of back pressure, with a focus on its practical applications in valve systems, common challenges, solutions, and future trends. It aims to provide industrial professionals with a comprehensive reference for optimizing fluid system design and operation.

1. Basic Definition and Core Connotation of Back Pressure

Back pressure refers to the reverse pressure exerted on the upstream fluid by downstream systems or devices during fluid flow, a key concept in fluid mechanics and engineering.

• Mechanical Essence: It is a pressure form where the direction of pressure transmission opposes the direction of fluid flow. This opposition hinders normal fluid movement, leading to increased upstream pressure and reduced flow velocity.

• Formation Context: In closed or semi-closed fluid systems, back pressure arises from the interaction of system structure, fluid properties, and flow status. For example, when fluid passes through equipment such as pipelines, valves, or pumps, downstream resistances (e.g., pipe elbows, cross-sectional changes, or throttling by devices) generate a reverse force, which is transmitted upstream as back pressure.

• Magnitude Relationship: Back pressure is generally proportional to downstream resistance: greater downstream resistance leads to more significant flow obstruction and higher back pressure; conversely, reduced downstream resistance lowers back pressure.

• Engineering Significance: Back pressure is not inherently "negative." In some scenarios, reasonable back pressure stabilizes fluid flow, controls velocity or pressure, and ensures system safety (e.g., preventing cavitation in pumps). However, excessively high back pressure can increase energy consumption, overload equipment, and even cause system failures—requiring targeted technical regulation.

2. Generation Mechanisms and Influencing Factors of Back Pressure

2.1 Generation Mechanisms

2.1.1 Flow Resistance: When fluid flows in a pipeline, frictional resistance against the pipe wall (along-range resistance) and obstruction from local structures (e.g., elbows, valves, or reducers) (local resistance) cause pressure loss downstream. This loss transmits a reverse pressure upstream, forming back pressure.

2.1.2 Downstream System Pressure: If the downstream container, equipment, or system itself has a certain pressure (e.g., pressure in a sealed tank or operating pressure of subsequent processes), it directly creates back pressure on the upstream fluid. For example, in boiler steam pipelines, the operating pressure of downstream steam-using equipment acts as the back pressure for steam transmission.

2.1.3 Fluid Inertia and Momentum Change: Sudden changes in fluid velocity (e.g., abrupt valve closure) cause a sharp change in fluid momentum, triggering the water hammer effect. This effect generates instantaneous high back pressure, which may impact pipelines and equipment.

2.2 Influencing Factors

Factor Category |

Specific Factors |

Impact on Back Pressure |

Pipeline Parameters |

Diameter, length, roughness, layout (number of elbows, slope) |

Longer, narrower, or rougher pipelines increase along-range resistance, raising back pressure; more elbows enhance local resistance, further increasing back pressure. |

Downstream Load |

Valve opening, pump head, container pressure |

Smaller valve openings or higher container pressure increase downstream resistance, leading to higher back pressure; fully open valves minimize back pressure. |

Fluid Properties |

Density, viscosity, temperature |

High-viscosity fluids (e.g., crude oil) have greater flow resistance than low-viscosity fluids (e.g., water), resulting in higher back pressure; high temperatures reduce viscosity (slightly lowering back pressure) but may alter pipeline resistance via thermal expansion. |

Flow Rate |

Fluid flow rate within the system |

Within a designed range, higher flow rates increase flow resistance and back pressure; flow rates exceeding design limits cause a sharp rise in back pressure, leading to system overload. |

3. Application Principles of Back Pressure in the Valve Field

Valves are core components for controlling fluid flow, pressure, and direction. Back pressure is closely linked to valve performance and function realization, with applications based on three core principles:

3.1 Using Back Pressure to Stabilize System Status

In pressure-sensitive fluid systems, stable back pressure prevents fluctuations in fluid velocity or pressure, ensuring process stability. For example, in the feed pipeline of a chemical reactor, the pressure inside the downstream reactor (i.e., back pressure) allows valves to adjust feed flow—balancing feed pressure with back pressure to avoid reaction instability caused by sudden feed pressure changes.

3.2 Regulating Back Pressure via Valves

Changes in valve opening directly alter fluid flow resistance, thereby adjusting back pressure:

• Reducing valve opening increases resistance to fluid passage, raising back pressure exerted by downstream on upstream.

• Increasing valve opening decreases resistance, lowering back pressure.

This principle enables active back pressure regulation to meet process requirements (e.g., maintaining stable pressure in steam heating systems).

3.3 Ensuring Valve Function via Back Pressure

Some valves rely on back pressure to operate:

• Back Pressure Valves (BPVs): Also known as pressure-stabilizing valves, they automatically adjust opening by sensing downstream back pressure, maintaining back pressure within a set range to ensure stable downstream system pressure.

• Check Valves: They use back pressure to prevent fluid backflow. When downstream pressure (back pressure) exceeds upstream pressure, the valve closes automatically to block reverse flow.

4. Specific Application Scenarios of Back Pressure in the Valve Field

4.1 Applications of Back Pressure Valves (BPVs)

BPVs are specifically designed to control system back pressure, maintaining downstream pressure at a set value. They are widely used in chemical, petroleum, water treatment, and pharmaceutical industries.

4.1.1 Working Principle

BPVs use springs, pneumatic, or hydraulic actuators to set a reference pressure (target back pressure).

• When downstream back pressure is lower than the set value, the valve is fully open, allowing fluid to flow freely.

• When downstream back pressure exceeds the set value, the valve closes slightly under reverse pressure, increasing flow resistance to reduce back pressure to the set range.

• If back pressure continues to rise, the valve can fully close to prevent overpressure.

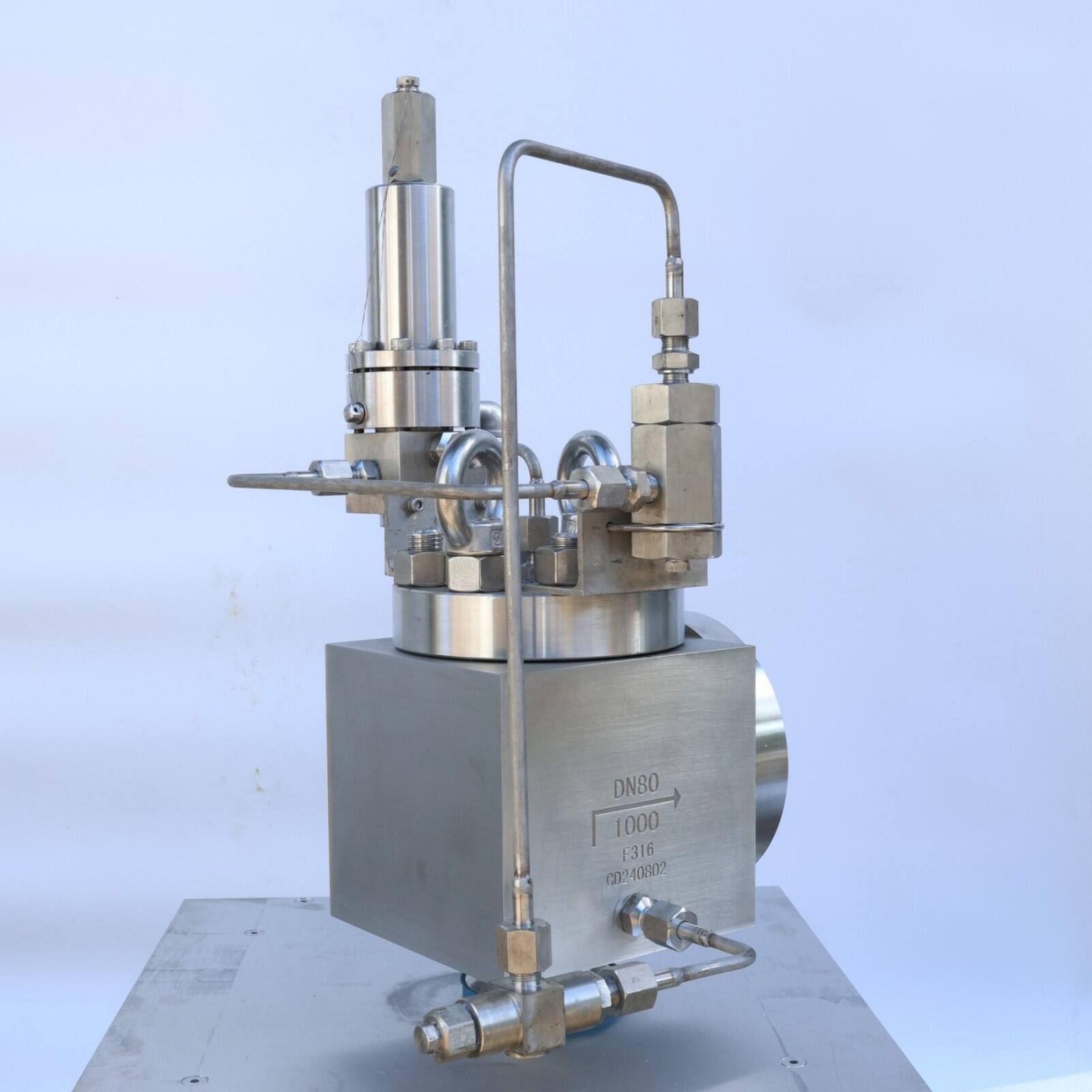

Figure 1: Schematic Diagram of Back Pressure Valve Operation

4.1.2 Typical Application Scenarios

• Chemical Reaction Systems: Continuous reactions require stable reactor pressure (back pressure) to ensure efficiency and product quality. BPVs installed on reactor discharge pipelines regulate back pressure, maintaining reactor pressure at 0.5–1.2 MPa (typical range) and avoiding product purity degradation or reaction runaway due to pressure fluctuations.

• Pump Outlet Pipelines: Centrifugal pumps are prone to cavitation (liquid vaporization caused by low inlet pressure) at low flow rates. Installing a BPV at the pump outlet maintains a minimum back pressure (usually 0.2–0.5 MPa), increasing the pump’s inlet pressure and preventing cavitation.

• Reverse Osmosis (RO) Water Treatment Systems: RO membranes require stable operating pressure (1.0–2.5 MPa for seawater desalination). BPVs installed at the concentrated water outlet of membrane modules adjust back pressure to control the pressure difference across the membrane, ensuring stable water permeability and preventing membrane damage from excessive pressure.

4.2 Synergistic Effect of Check Valves and Back Pressure

Check valves prevent fluid backflow, with their operation directly dependent on the pressure difference between upstream and downstream (i.e., the relationship between back pressure and upstream pressure):

• When upstream pressure downstream back pressure: The valve opens, allowing normal fluid flow.

• When upstream pressure < downstream back pressure: The valve closes under back pressure, blocking reverse flow.

4.2.1 Application Scenarios

• Boiler Feedwater Systems: Check valves installed at the outlet of boiler feedwater pumps prevent high-pressure steam (back pressure, typically 3–10 MPa) from flowing back into the feedwater pipeline when the pump stops. This avoids damage to the pump impeller or pipeline overpressure.

• Hydraulic Systems: In hydraulic pipelines, check valves prevent hydraulic oil from backflowing due to the load pressure (back pressure) of downstream actuators (e.g., hydraulic cylinders). For example, in crane hydraulic systems, check valves use back pressure to lock the boom position, preventing heavy loads from falling.

• Drainage Pipelines: Check valves installed at rainwater or sewage discharge outlets close when river water levels rise (creating back pressure), preventing river water from backflowing into the drainage system.

4.3 Correlation Between Safety Valves and Back Pressure

Safety valves are critical for system safety—they open automatically to relieve pressure when system pressure exceeds the set value. Superimposed back pressure (back pressure in the safety valve’s outlet pipeline) affects the valve’s opening pressure and discharge capacity, requiring careful consideration during design and selection.

4.3.1 Impact of Superimposed Back Pressure

• Fixed Back Pressure: Stable pressure from the downstream system (e.g., pressure in a flare system). Excessively high fixed back pressure increases the safety valve’s opening pressure, delaying pressure relief.

• Variable Back Pressure: Pressure fluctuations caused by fluid flow during safety valve discharge. Sudden drops in variable back pressure can cause the valve to "chatter" (repeated opening and closing), damaging the seal.

4.3.2 Countermeasures

• Valve Selection: Use balanced safety valves (equipped with bellows or piston structures) to offset the impact of superimposed back pressure, ensuring stable opening pressure. These valves are suitable for high-back-pressure scenarios (e.g., chemical flare systems with superimposed back pressure 30% of the set pressure).

• Pipeline Design Optimization: Increase the outlet pipe diameter and reduce elbows to minimize resistance and lower superimposed back pressure. For back pressure exceeding design limits, install back pressure balancing valves or pressure relief bypasses.

4.4 Back Pressure Regulation by Control Valves

Control valves adjust opening via electrical or pneumatic signals to change fluid flow and indirectly regulate system back pressure. They are widely used in industrial automation control.

4.4.1 Pressure Control Loops

In pressure control loops, control valves adjust opening based on signals from downstream pressure sensors to regulate back pressure. For example, in steam heating systems, control valves installed on steam outlet pipelines adjust opening according to the heating equipment’s temperature demand (indirectly reflecting steam pressure), maintaining steam back pressure at 0.3–0.8 MPa (typical range) and ensuring stable heating temperatures.

4.4.2 Flow-Back Pressure Linkage Control

In systems where flow and back pressure are coupled, control valves enable coordinated regulation. For example, in natural gas transmission pipelines:

• When downstream gas consumption increases (higher flow rate), pipeline back pressure decreases. The control valve closes slightly to increase resistance, stabilizing back pressure.

• When gas consumption decreases, the valve opens wider to reduce back pressure, preventing pipeline overpressure.

4.5 Balance Between Pressure Reducing Valves (PRVs) and Back Pressure

PRVs reduce high upstream fluid pressure to the required downstream pressure, with their stability dependent on stable downstream back pressure. When back pressure fluctuates, PRVs adjust opening via feedback mechanisms to maintain stable outlet pressure.

4.5.1 Application Scenarios

• Urban Gas Systems: Main gas pipelines operate at high pressure (e.g., 0.4 MPa), while residential users require low pressure (e.g., 2 kPa). PRVs installed at community or building entrances reduce pressure. When downstream gas consumption increases (higher flow rate), downstream back pressure decreases—the PRV opens wider to increase flow and maintain stable outlet pressure. Conversely, when consumption decreases, the PRV closes slightly to avoid excessive outlet pressure.

• Hydraulic Systems: Hydraulic pumps output high pressure (e.g., 15–30 MPa), while actuators (e.g., hydraulic motors) require low pressure (e.g., 2–5 MPa). PRVs reduce pressure and offset downstream back pressure fluctuations, ensuring stable actuator pressure.

Figure 2: Schematic Diagram of Pressure Reducing Valve in Urban Gas Systems

5. Challenges and Solutions for Back Pressure in Valve Applications

5.1 Common Challenges

5.1.1 Increased Energy Consumption Due to Excessive Back Pressure: In pipelines downstream of power equipment (e.g., pumps, compressors), excessive valve resistance (e.g., insufficient opening) creates high back pressure. For example, a centrifugal pump operating under back pressure 20% higher than the design value may see a 15–20% increase in power consumption, raising operational costs.

5.1.2 System Instability Caused by Back Pressure Fluctuations: In pressure-sensitive processes (e.g., chemical synthesis, pharmaceutical purification), frequent back pressure fluctuations disrupt reaction conditions. For example, fluctuations in the top pressure (back pressure) of a distillation column cause temperature changes, reducing distillate purity by 5–10%.

5.1.3 Valve Damage from Transient Back Pressure (Water Hammer): Abrupt valve closure triggers the water hammer effect, generating transient back pressure several times higher than normal pressure. This can damage valve seals, bend valve stems, or even rupture pipelines. For example, emergency closure of steam pipeline valves may generate transient back pressure exceeding 15 MPa, causing valve leakage.

5.1.4 Mismatch Between Back Pressure and Valve Selection: Using valves with design back pressure ranges incompatible with actual system conditions leads to malfunctions. For example, ordinary check valves may leak under high back pressure ( 10 MPa) due to insufficient sealing force; safety valves fail to open accurately when superimposed back pressure exceeds design limits.

5.2 Solutions

5.2.1 Optimize Valve Selection:

◦ For high-back-pressure systems: Use balanced safety valves or high-pressure check valves (rated pressure 10 MPa).

◦ For systems with large back pressure fluctuations: Use control valves with pressure compensation (e.g., cage-type control valves), which offset back pressure changes via spool design.

5.2.2 Rational Pipeline and Valve Layout:

◦ Reduce local resistance: Use large-radius elbows (radius ≥ 3× pipe diameter) and shorten pipeline length.

◦ Install buffer devices: Add expansion joints or water hammer arresters upstream/downstream of valves to absorb transient back pressure impacts.

5.2.3 Adopt Automatic Control Technologies:

◦ Integrate pressure sensors, PLC control systems, and valves to monitor back pressure in real time and adjust valve opening. For example, in reactor systems, pressure sensors transmit back pressure signals to controllers, which drive BPVs to maintain back pressure within ±0.05 MPa of the set value.

5.2.4 Regular Maintenance and Debugging:

◦ Inspect valve seals and spool wear quarterly; replace damaged components promptly to avoid abnormal back pressure.

◦ Calibrate valve settings (e.g., BPV spring preload, safety valve pop-off pressure) semi-annually to match system back pressure requirements.

6. Application Trends of Back Pressure in the Valve Field

With the development of industrial automation and intelligence, back pressure applications in the valve field are evolving in four key directions:

6.1 Intelligent Back Pressure Control: Integrating IoT and big data technologies, valves collect real-time data on back pressure, flow rate, and temperature. Cloud platforms analyze data to enable remote adjustment and AI-driven predictive maintenance. For example, smart BPVs use historical data to predict back pressure trends, adjusting opening in advance to avoid fluctuations.

6.2 Efficient and Energy-Saving Valve Design: To address energy waste from high back pressure, new valves adopt low-flow-resistance structures (e.g., streamlined spools, smooth internal channels). For example, ball valves have 30–50% lower flow resistance than gate valves, reducing back pressure and improving pump efficiency by 8–12% in large-flow systems.

6.3 Back Pressure Adaptation Technologies for Extreme Conditions: In extreme environments (e.g., nuclear power, deep-sea oil exploration), valves must withstand high back pressure ( 50 MPa) and harsh fluid properties (e.g., corrosive media). Material innovations (e.g., superalloys, ceramic coatings) and structural optimizations (e.g., multi-stage sealing) enhance valve back pressure resistance and reliability.

6.4 System-Integrated Back Pressure Optimization: Incorporate valve back pressure control into overall fluid system design. Use computational fluid dynamics (CFD) to simulate back pressure distribution, optimizing valve layout and parameters for maximum system efficiency. For example, in urban water supply systems, CFD simulations of regional back pressure guide PRV placement, reducing pipeline energy consumption by 10–15%.

7. Conclusion

Back pressure is a critical parameter in fluid systems, with its generation closely linked to system resistance, downstream load, and fluid properties. In the valve field, back pressure is integral to valve function, system regulation, and safety—supporting precise pressure control by BPVs, backflow prevention by check valves, pressure relief by safety valves, and automated adjustment by control valves.

However, excessive back pressure, fluctuations, or mismatches with valves can lead to increased energy consumption, system instability, and equipment damage. Addressing these issues requires optimized valve selection, rational design, automatic control, and regular maintenance.

Looking ahead, intelligent, energy-efficient, and extreme-condition-adapted back pressure control technologies will drive innovation in the valve industry. These advancements will enable more precise, reliable, and efficient back pressure management, providing robust support for the safe and stable operation of industrial fluid systems worldwide.

Hot News

Hot News