In the realm of natural gas transmission and distribution, the demand for valves that can ensure safe, efficient, and stable operation is paramount. Among the various valve types, the fixed flanged ball valve with a pressure rating of 1500LB stands out as a crucial component, playing an irreplaceable role in natural gas systems.

Superior Structural Design for Optimal Performance

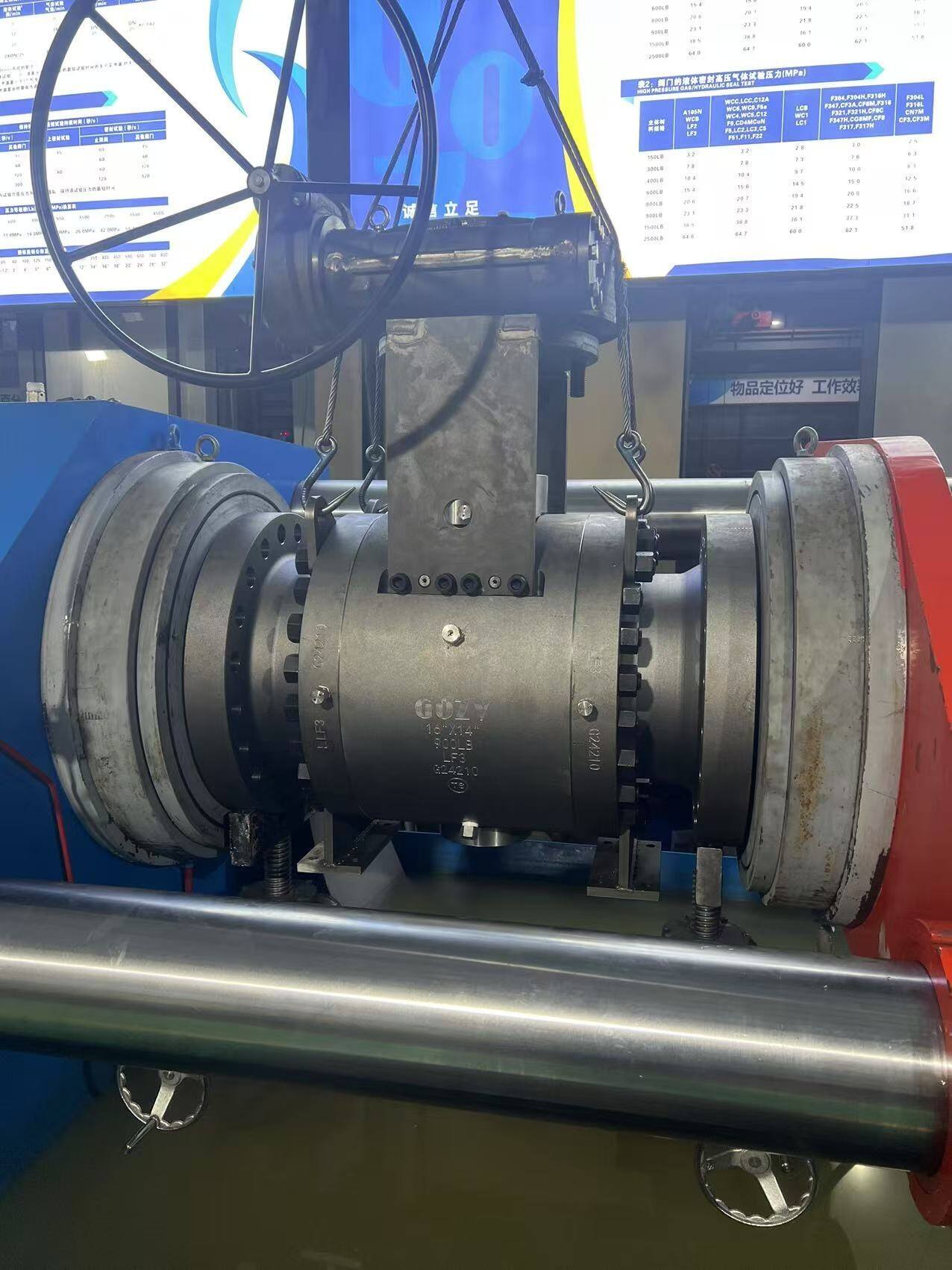

The fixed flanged ball valve 1500LB features a robust structural design. Unlike floating ball valves, the ball in this fixed type is held in place by upper and lower bearings, which significantly reduces the friction between the ball and the seat during operation. This design not only enhances the valve's service life but also ensures smooth opening and closing, even under high-pressure natural gas conditions.

The flange connection design adheres to international standards, enabling easy and secure installation into pipelines. The 1500LB pressure rating indicates that the valve can withstand extremely high pressures, making it well-suited for the high-pressure environments commonly found in natural gas transmission, where maintaining pipeline integrity is of utmost importance.

Exceptional Sealing for Safety and Efficiency

Sealing performance is a critical factor for any valve used in natural gas applications, as even a minor leak can lead to safety hazards and significant energy losses. The fixed flanged ball valve 1500LB employs advanced sealing technology. The seats are typically made of high-performance materials such as PTFE or metal alloys, which offer excellent wear resistance and sealing capabilities.

When the valve is closed, the ball presses tightly against the seats, creating a reliable seal that prevents natural gas from leaking. This exceptional sealing performance not only guarantees the safety of the natural gas system but also contributes to the efficient utilization of natural gas resources by minimizing waste.

Material Selection for Durability and Corrosion Resistance

Natural gas, especially when containing impurities or in certain environments, can be corrosive to valves. To address this, the fixed flanged ball valve 1500LB is constructed using high-quality materials. The body and ball are often made of alloy steels or stainless steels, which possess excellent corrosion resistance and mechanical strength.

These materials can withstand the corrosive effects of natural gas over long periods, ensuring the valve's structural integrity and performance stability. Whether in onshore natural gas pipelines or offshore platforms, this valve can maintain reliable operation, reducing maintenance costs and downtime.

Wide Application in Natural Gas Industry

The fixed flanged ball valve 1500LB finds extensive application in various segments of the natural gas industry. It is commonly used in long-distance natural gas transmission pipelines, where it serves as a key component for controlling the flow of natural gas. In gas processing plants, it helps regulate the flow during purification and processing stages. Additionally, it is employed in natural gas storage facilities and distribution networks, ensuring the safe and efficient delivery of natural gas to end-users.

Its ability to handle high pressures and its reliable sealing performance make it an ideal choice for critical points in natural gas systems, where any failure could have severe consequences.

Conclusion

The fixed flanged ball valve 1500LB is a highly reliable and efficient valve solution for natural gas applications. With its superior structural design, exceptional sealing performance, durable material selection, and wide applicability, it meets the stringent requirements of the natural gas industry. As the demand for natural gas continues to grow and the industry places higher emphasis on safety and efficiency, the fixed flanged ball valve 1500LB will undoubtedly continue to play a vital role in ensuring the smooth operation of natural gas systems worldwide.

Hot News

Hot News