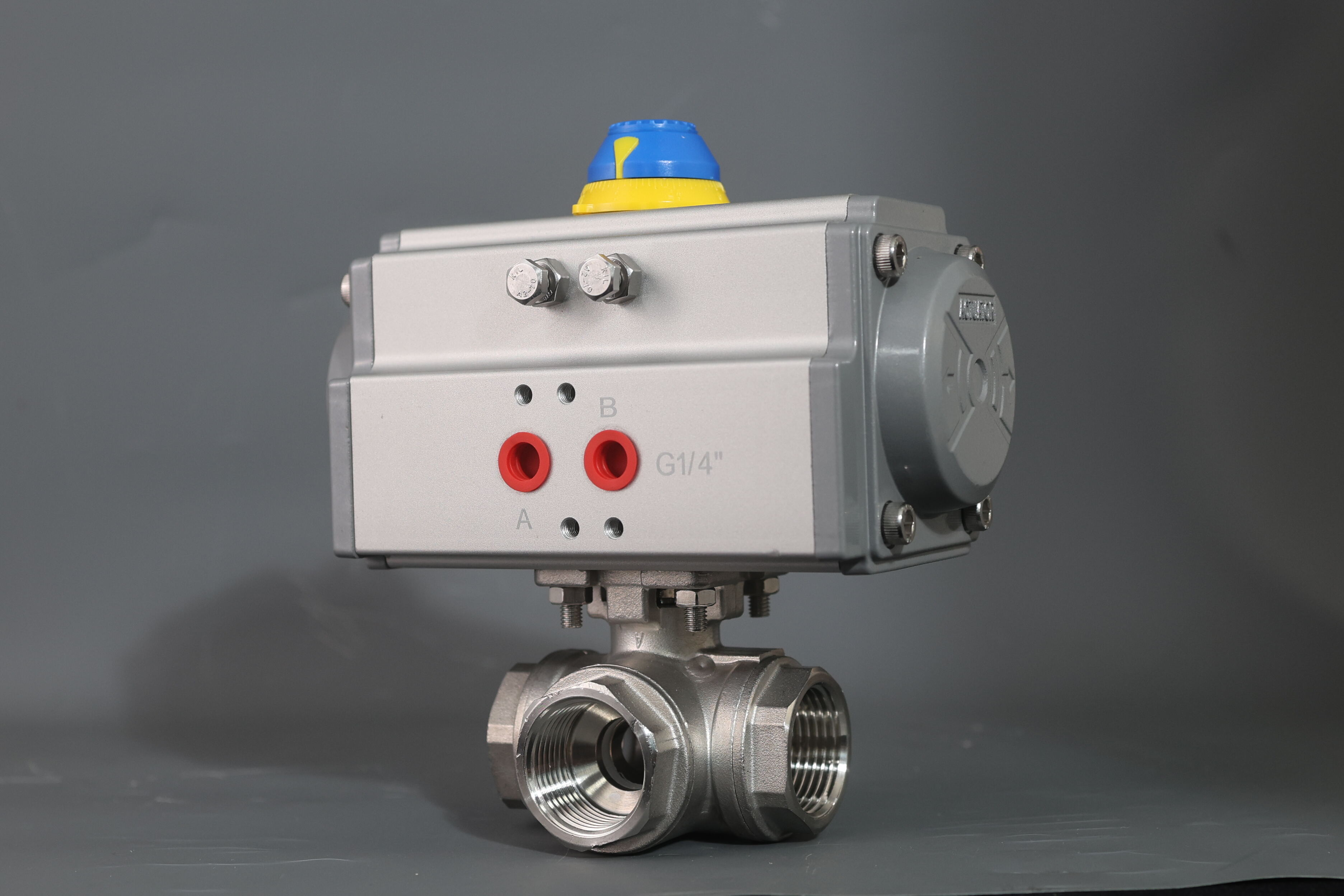

manual ball valve

A manual ball valve is a crucial mechanical device designed for controlling fluid flow in various industrial and commercial applications. This robust valve type features a spherical disc within its body, which rotates on its axis when operated by a manual lever or handle. The sphere contains a port through which fluid can flow when aligned with the inlet and outlet ports of the valve body. When the handle is turned 90 degrees, the solid part of the sphere blocks the flow path, effectively stopping the fluid flow. These valves are renowned for their reliable sealing capabilities, quick quarter-turn operation, and minimal pressure drop when fully open. Manual ball valves are manufactured from various materials including brass, stainless steel, PVC, and other engineered plastics, making them suitable for diverse applications and media types. They excel in applications requiring tight shutoff and are commonly found in water treatment facilities, chemical processing plants, oil and gas operations, and general industrial processes. The straightforward design ensures long-term reliability with minimal maintenance requirements, while their compact structure makes them ideal for installations where space is limited.