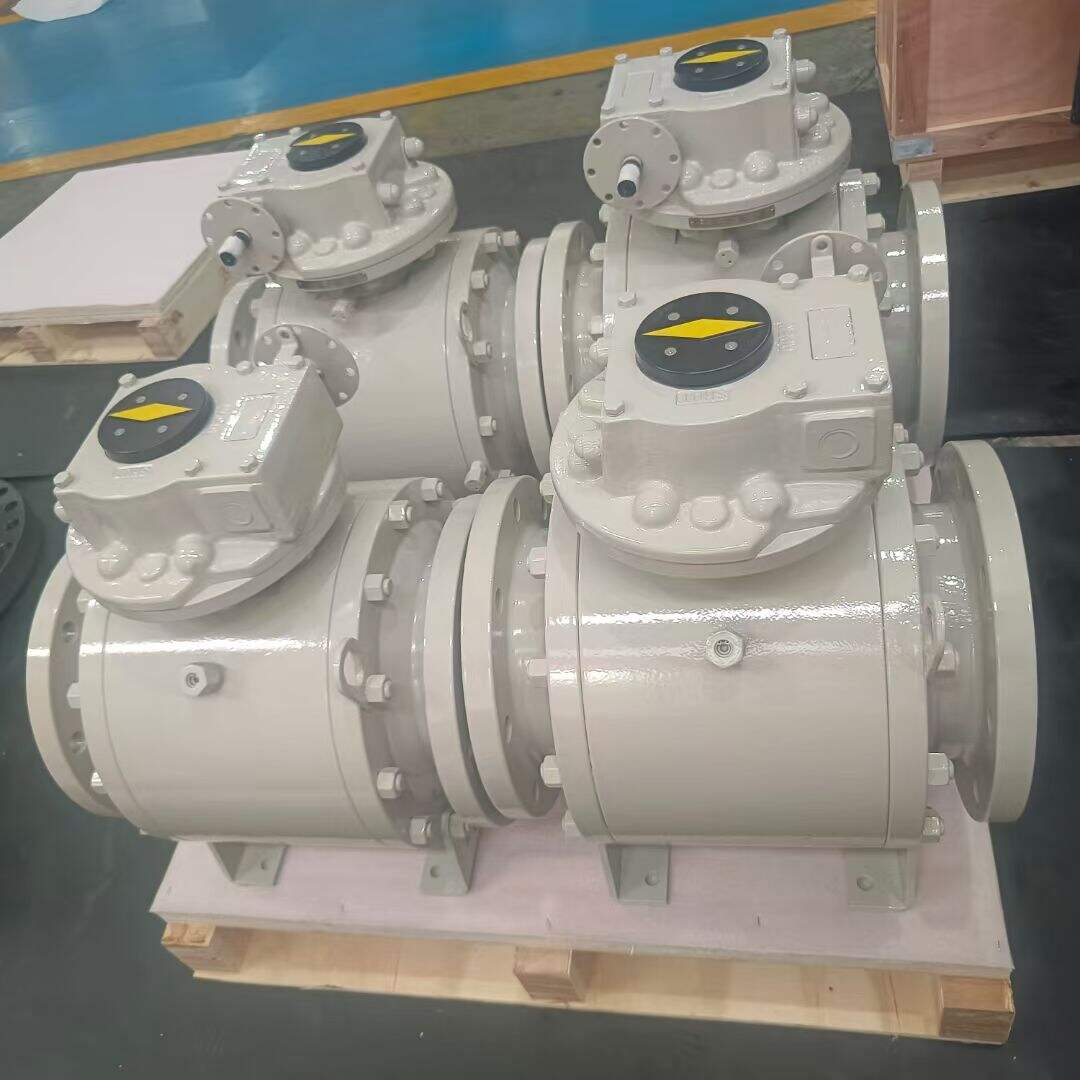

conventional spring loaded relief valve

A conventional spring loaded relief valve is a critical safety device designed to protect pressure vessels, piping systems, and equipment from excessive pressure. Operating on a straightforward mechanical principle, these valves incorporate a spring mechanism that maintains closure against normal system pressure. When the system pressure exceeds a predetermined threshold, it overcomes the spring force, allowing the valve to open and release excess pressure. The valve consists of several key components, including the valve body, spring, disc, and adjusting mechanism. The spring tension, which determines the pressure at which the valve will open, can be precisely calibrated to meet specific system requirements. These valves respond rapidly to pressure increases, providing reliable protection against system overpressure. They are self-actuating, requiring no external power source or control system to function. Once the system pressure returns to normal levels, the spring automatically reseats the valve, ensuring system integrity. Conventional spring loaded relief valves find widespread application across various industries, including oil and gas, chemical processing, power generation, and pharmaceutical manufacturing. Their robust design and reliable operation make them an essential component in pressure management systems, contributing significantly to plant safety and operational continuity.