Core Parameters & Features

● Compatible Media: Liquids, Gases (Hydrogen, Nitrogen, etc.)

● Operating Temp: ≤425°C

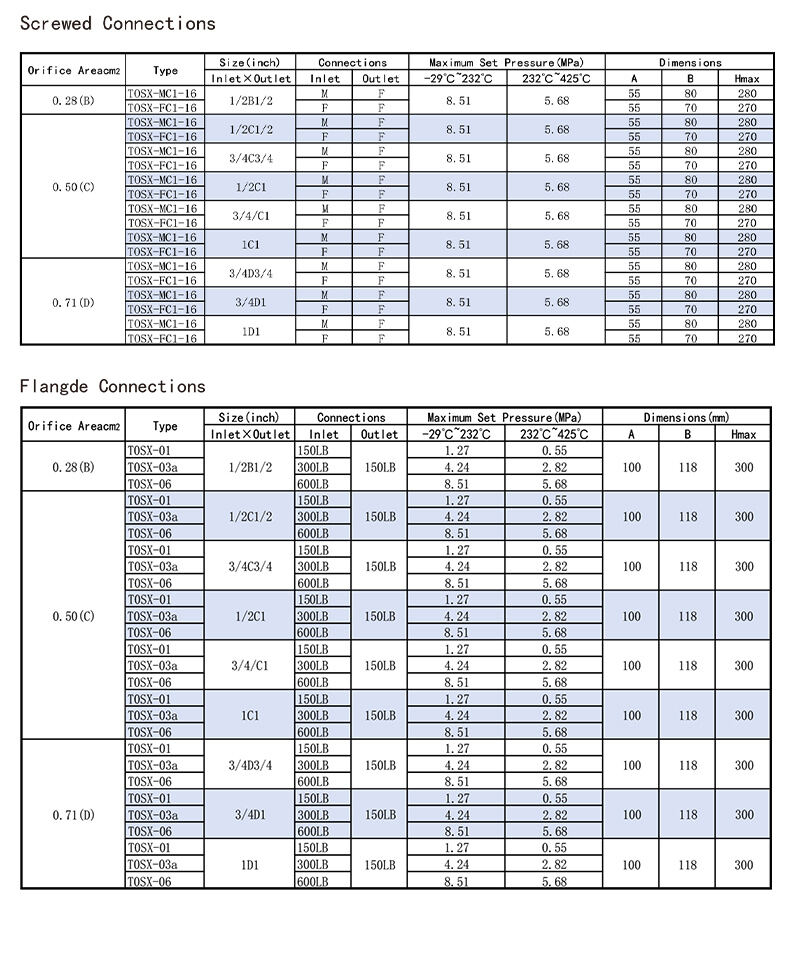

● Working Pressure: 1.6MPa~10MPa (232psi~1450psi)

● High Backpressure Performance

○ Liquids: 70% of set pressure

○ Steam/Gases: 50% of set pressure

○ Thermal Expansion: 90% of set pressure

● Size Range

○ Threaded Ends: 1/2"~1"

○ Flange Ends: 1/2"~3/4" (fits DN15~DN20)

● Sealing Advantage: Rubber/PTFE Soft Seal (Low Leakage, Easy Maintenance)

Application Scenarios

Water Supply Systems | Petrochemical Industry | Paper Mills | Fluid Processing Equipment Overpressure Protection

Loose Sleeve Pressure Relief Valve – Comprehensive Product Manual

Product Introduction

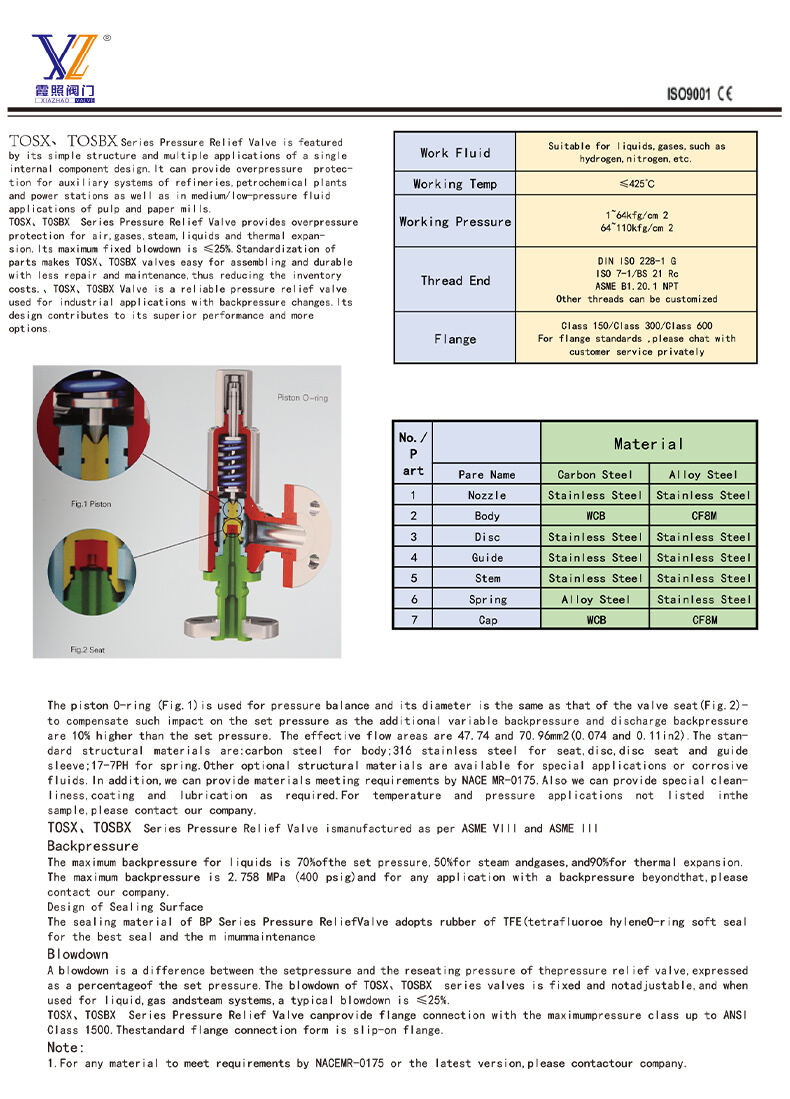

The Loose Sleeve Pressure Relief Valve is a premium safety-critical component engineered to safeguard industrial piping systems and equipment from catastrophic overpressure damage. It is specifically designed to excel in applications involving liquid media and high back pressure conditions . Its core innovation lies in the loose sleeve connection design and the balanced piston structure , which together provide stable performance, precise pressure control, and reliable sealing where conventional valves often fail.

Detailed Overview

The valve operates on a sophisticated yet reliable principle: it automatically actuates to release excess pressure when system pressure exceeds the preset threshold and seamlessly reseals once pressure returns to the safe operating range. The loose sleeve design minimizes pipeline stress caused by thermal expansion and contraction, while supporting flexible installation. Ideal for a wide spectrum of industries—including petrochemical, water supply, hydraulic, and fire protection—this valve delivers unparalleled safety and operational stability for critical processes.

Product Features

1. Stable Operation Under High Back Pressure

Incorporates an advanced balanced piston mechanism that actively compensates for back pressure fluctuations.

Maintains consistent set pressure accuracy even when back pressure reaches up to 70% of the set pressure for liquid media.

2. Precise Pressure Control

Achieves exceptional control accuracy with an opening-closing differential pressure of ≤25% .

Utilizes a high-precision stainless steel spring and precision-machined guiding structure.

3. Reliable Sealing Performance

Features a multi-layer sealing structure combining PTFE or FKM soft sealing materials with an O-ring piston seal design.

Ensures bubble-tight, zero-leakage performance even in high back pressure, high-temperature, or corrosive liquid environments.

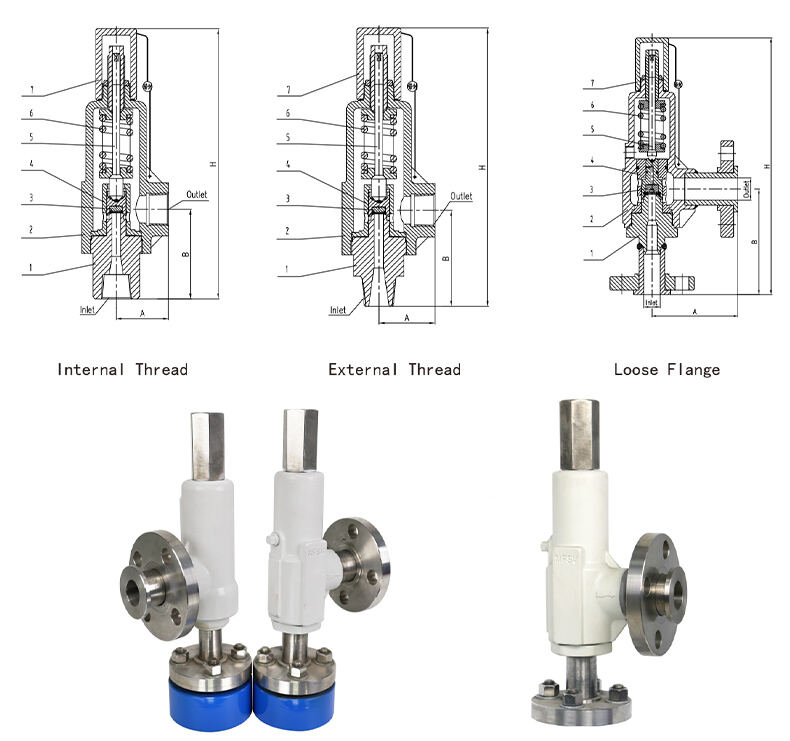

4. Easy Installation & Maintenance

Supports multiple connection methods: Flange, Internal Thread, and External Thread .

Modular structure allows for easy disassembly and maintenance without specialized tools, reducing downtime and costs.

5. Versatile Material Options

Available in a range of materials: Carbon Steel (WCB) for general use, Stainless Steel (304/316) for corrosion resistance, and Alloy Steel (CF8M) for high-temperature/pressure conditions.

Tailored to handle various liquid media including water, oil, and chemical solutions.

Core Advantages vs. Traditional Valves

| Parameter / Index | Loose Sleeve Pressure Relief Valve | Traditional Direct Spring Relief Valve | Applicability in Liquid High Back Pressure Conditions |

| Back Pressure Compensation | Supports back pressure up to 70% of set pressure with active compensation. | Poor compensation; back pressure 30% of set pressure causes set pressure drift. | Excellent: Stable operation without pressure deviation. |

| Pressure Control Precision (Opening-Closing ΔP) | ≤25% | 35% - 50% | Superior: Precise control of liquid system pressure. |

| Sealing Performance (Liquid Media) | Multi-layer seal (PTFE/FKM + O-ring), zero leakage. | Single-layer metal/soft seal, prone to leakage under high back pressure. | Reliable: Prevents leakage and environmental pollution. |

| Material Adaptability | Multiple materials (304/316 SS, alloy steel) for corrosive resistance. | Limited options; common carbon steel is prone to corrosion. | Strong: Suitable for various corrosive media. |

| Installation Flexibility | Multiple connection methods; loose sleeve design reduces pipeline stress. | Single connection method; rigid connection is affected by pipeline deformation. | High: Convenient for retrofitting and complex layouts. |

| Maintenance Cost | Modular structure, easy disassembly, low frequency of parts replacement. | Complex disassembly; high frequency of spring/seal replacement under high back pressure. | Low: Reduces downtime and long-term operation cost. |

Application Scenarios & Case Studies

1. Petrochemical Industry: Corrosive Liquid Process Pipelines

Application: Crude oil refining process pipelines, chemical reagent storage, offshore platform transfer lines.

Case Study: A plant in East China replaced conventional valves in a corrosive benzene line (60% back pressure) with stainless steel (316L) loose sleeve valves. Result: Stable pressure control (ΔP ≤25%), zero leakage, and service life extended by over 3 years .

2. Water Supply & Circulation Systems: Booster Pump Protection

Application: Municipal water networks, industrial circulating water systems, pump outlets.

Case Study: A South China water treatment plant installed valves at booster pump outlets to counteract pressure spikes (up to 0.8MPa). Valves opened within 0.1 seconds of a spike, protecting pumps and pipelines.

3. Hydraulic Systems: High-Pressure Liquid Power Units

Application: Injection molding machines, hydraulic presses.

Case Study: A precision injection molding plant in Guangdong integrated the valve into its hydraulic circuit. The balanced design eliminated actuator interference, stabilized clamping pressure, and reduced scrap rates by 15% .

4. Fire Protection Systems: High-Rise Building Water Networks

Application: Fire sprinkler systems, fire hydrant networks, vertical risers.

Case Study: A 50-story building in Shanghai used the valves in its fire water system (70% back pressure). The valves ensured uniform pressure distribution across all floors and performed reliably during a fire drill.

5. Other Industrial Applications

HVAC chilled/hot water pipelines, power plant cooling water systems, food & beverage processing lines (with food-grade materials).

Technical Specifications

| Parameter Item | Details |

| Size Range | DN15 – DN200 (1/2" – 8") |

| Pressure Range | 0.1MPa – 1.6MPa |

| Applicable Media | Liquid (water, oil, chemical solutions, etc.) |

| Operating Temperature | -20℃ – 120℃ (Higher with alloy steel) |

| Connection Type | Flange, Internal Thread, External Thread |

| Main Body Materials | Carbon Steel (WCB), Stainless Steel (304/316), Alloy Steel (CF8M) |

| Set Pressure Range | 0.1MPa – 1.6MPa |

| Back Pressure Range | Up to 70% of set pressure (for liquid media) |

| Pressure Control Accuracy | Opening-closing differential pressure ≤25% |

Selection & Installation Guidelines

1. Selection Criteria

● Back Pressure Compatibility: Select valves rated for back pressure up to 70% of the set pressure for liquid media.

● Material Selection: Choose based on medium: WCB for water, 304/316 SS for corrosive liquids, alloy steel for high temps (up to 425℃).

● Pressure Control Precision: Prioritize valves with ΔP ≤25% for stable control under fluctuating back pressure.

● Flow Capacity: Select valves that can handle the required flow rate at 10-20% above the set pressure.

2. Installation Best Practices

● Install in the correct flow direction (as indicated by the arrow on the valve body).

● Ensure secure connections: properly torque flange bolts; use appropriate sealant on threads.

● Maintain sufficient space around the valve for maintenance.

● Size the discharge pipe correctly to avoid additional back pressure buildup.

3. Maintenance & Care

● Regularly inspect sealing surfaces and O-rings for wear or damage; replace promptly.

● Keep the valve body and internals clean to prevent blockages.

● For valves inactive for extended periods, re-calibrate the set pressure before re-commissioning.

● Conduct annual comprehensive inspections and performance tests per industrial standards.

Qualifications & Certifications

Our valves are manufactured in strict compliance with international standards, holding the following certifications:

● ISO9001:2015 Quality Management System Certification

● CE Certification

● Pressure Equipment Directive (PED) Certification

● Compliant with API, ASME, and other industrial safety standards.

Contact Information

Shanghai Xiazhao Valve Co., Ltd.

Address: Jiading District, Shanghai, China

Phone: +86-18018653319

Email: [email protected]

Website: www.ruisellovalve.com

For product inquiries, quotations, or technical support, please contact our professional customer service team for tailored solutions and efficient service.