Bullet Points:

✅ Precise Pressure Control: Relieves excess pressure instantly to protect your equipment.

✅ Built for Demanding Environments: Ideal for high-pressure steam, oil, gas, and chemical applications.

✅ Rugged & Reliable Construction: Ensures long service life and minimal maintenance.

✅ Certified Safety: Meets international safety standards (e.g., ASME, PED)

Product Information

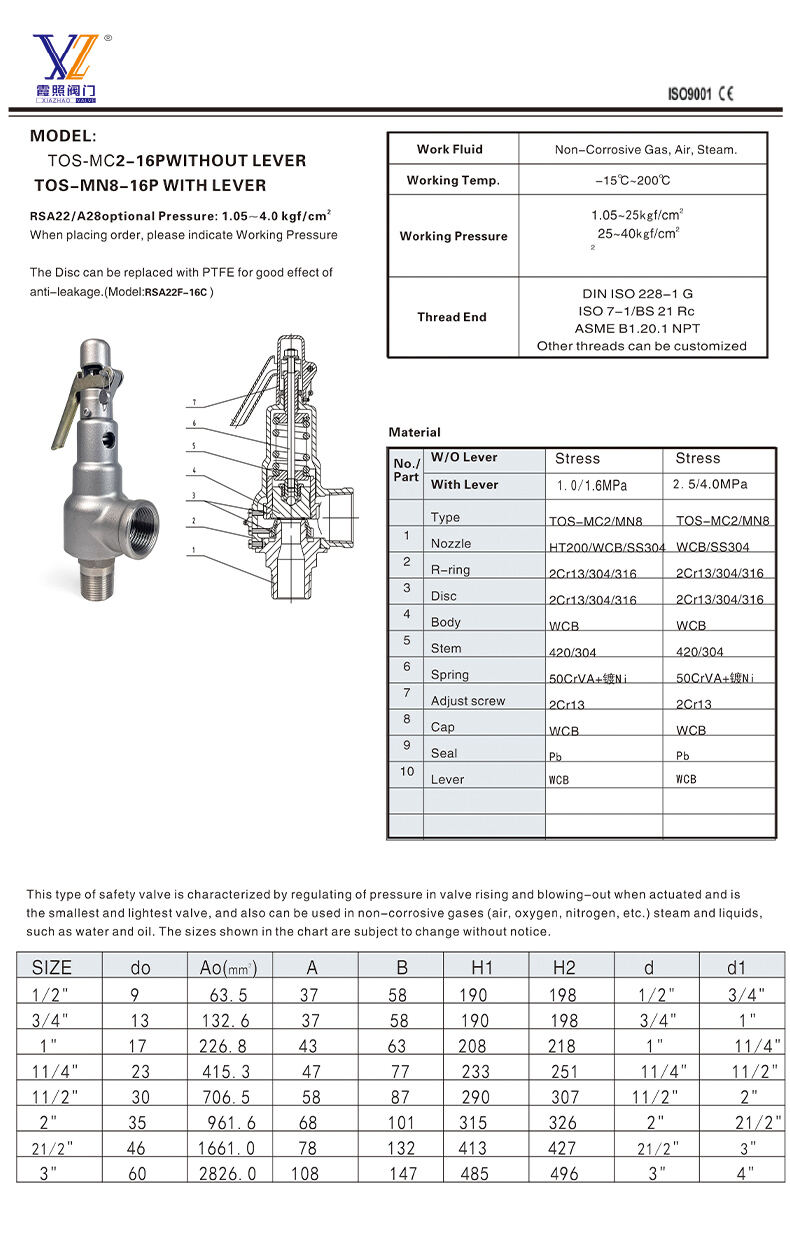

| Parameter | Specification |

| Model | XZ-PRV100 Series |

| Pressure Rating | Up to 600 PSI |

| Connection Type | Flanged, NPT, Socket Weld |

| Body Material | Stainless Steel, Carbon Steel |

| Set Pressure Tolerance | ±3% |

| Operating Temperature | -20°F to 750°F |

| Pressure Range | 50 - 600 PSI |

| Size | 1/2" to 2" NPT] |

| Material | Stainless Steel 316 / Carbon Steel |

Prevent Leakage & Extend Lifespan: Xiazhao Valve Threaded Steam Relief Valve Maintenance Manual

Introduction: Threaded Steam Relief Valve – The "Invisible Guardian" of Industrial Safety Production

In industrial fields such as chemical engineering, food processing, and energy, the stable operation of steam systems is directly related to production safety and efficiency. As a core equipment to ensure the pressure stability of steam systems, the Threaded Steam Relief Valve acts like a "safety sentinel" that releases pressure in a timely manner when the system pressure exceeds the limit, avoiding malignant accidents such as equipment explosion and steam leakage. However, neglecting its maintenance can lead to failures even for high-quality valves, which not only shortens the service life but also lays serious safety hazards and causes production suspension losses.

Shanghai Xiazhao Valve Co., LTD has been deeply engaged in the valve field for many years, focusing on providing high-quality threaded steam relief valves and a full set of technical services. We deeply understand the importance of maintenance to valve performance. Therefore, combining with actual industrial application scenarios, this article will detailedly analyze common faults, maintenance steps and precautions of threaded steam relief valves, and share real cases, helping industrial users, equipment maintenance personnel and engineering procurement personnel easily master practical methods to achieve dual guarantees of valve "life extension" and production safety.

I. Common Fault Analysis of Threaded Steam Relief Valves

During long-term use, threaded steam relief valves are prone to various faults affected by working conditions, installation, maintenance and other factors. The following are the 7 most common faults in industrial scenarios. Combined with the maintenance experience of Xiazhao Valve's technical team, detailed cause analysis and solutions are given:

1. Leakage (Broken Sealing Face)

Fault Performance: Steam leaks from the valve sealing face, leading to unstable system pressure and energy waste.

Cause Analysis: ① The sealing face is worn or scratched, mostly caused by the scouring of impurities in the medium; ② The sealing ring is aged, and the material deteriorates under long-term high-temperature environment; ③ The sealing face is not cleaned thoroughly during installation, leaving foreign objects.

Solution: ① For mild wear, professional tools can be used to grind the sealing face to restore sealing performance; ② When the wear is severe or the sealing ring is aged, replace the original spare parts of Xiazhao Valve (the original spare parts are made of high-temperature and corrosion-resistant materials with better adaptability); ③ After replacement or grinding, recheck the sealing performance. Xiazhao's threaded steam relief valve adopts a double-sealing structure design, which can reduce the leakage probability by 30% and reduce such faults from the source.

2. Improper Installation

Fault Performance: The valve opens insensitively, releases pressure incompletely, or vibrates during operation.

Cause Analysis: ① Non-vertical installation leads to uneven force on the valve disc; ② Excessive resistance during pipeline connection affects steam circulation; ③ Impurities and rust in the pipeline are not removed during installation, blocking the valve core.

Solution: ① Reinstall the valve vertically according to Xiazhao Valve's installation guide (vertical installation is the key to ensuring pressure relief performance); ② Adjust the pipeline connection method to reduce resistance components such as elbows and reducers; ③ Disassemble the valve, thoroughly clean the pipeline and valve core impurities, and then reinstall.

3. High Temperature Adaptation Problem

Fault Performance: The sealing performance of the valve decreases and components deform under high-temperature working conditions.

Cause Analysis: The selected valve model is not suitable for the actual high-temperature working conditions, leading to the failure of sealing parts, springs and other components under high temperature.

Solution: Replace the Xiazhao threaded steam relief valve model suitable for high-temperature working conditions (Xiazhao provides a variety of high-temperature resistant series, which can withstand temperatures above 300℃ and meet the needs of different industrial scenarios); if replacement is not possible temporarily, the maintenance and inspection cycle needs to be shortened to detect component deformation in time.

4. Improper Opening Pressure

Fault Performance: The valve opens in advance (pressure does not reach the threshold) or opens late (pressure exceeds the threshold but does not act).

Cause Analysis: ① Improper adjustment of spring preload; ② Spring fatigue failure; ③ Failure to combine with the actual system pressure during commissioning.

Solution: ① Professional and technical personnel re-adjust the spring preload to ensure that the opening pressure matches the system working pressure; ② Check the spring status, and replace the original Xiazhao spring if fatigue or deformation occurs; ③ Use a precision pressure gauge during commissioning, and set the pressure strictly according to the system design pressure.

5. Valve Disc Vibration

Fault Performance: The valve disc vibrates during valve operation, accompanied by abnormal noise, affecting the stability of pressure relief.

Cause Analysis: ① The valve is not installed firmly, and the fixing bolts are loose; ② Pipeline vibration is transmitted to the valve; ③ The gap between the valve disc and the valve seat is too large.

Solution: ① Tighten the valve fixing bolts to ensure firm installation; ② Install shock absorption components at the connection between the pipeline and the valve to reduce vibration transmission; ③ Check the gap between the valve disc and the valve seat, and if it exceeds the standard, perform grinding adjustment or replace components.

6. Dirt on Sealing Face

Fault Performance: Poor sealing, leakage, and unsmooth valve opening.

Cause Analysis: Impurities, oil stains, etc. in the steam medium adhere to the sealing surface, or scale accumulates due to long-term non-cleaning.

Solution: Disassemble the valve, use special cleaning tools (such as brushes, organic solvents) to clean the sealing surface, valve core and other components to ensure no residual impurities; reassemble after cleaning and check the sealing performance. Regular cleaning is recommended to avoid dirt accumulation.

7. Over Re-seating Pressure

Fault Performance: The valve cannot reset normally after pressure relief, and there is still slight leakage.

Cause Analysis: Improper position of the reset ring, or fatigue and deformation of the reset spring.

Solution: ① Adjust the position of the reset ring to ensure that it fits the valve disc accurately; ② Check the reset spring, and replace the original Xiazhao spare parts if it fails; ③ Re-commission the valve reset performance to ensure that it can reset quickly and tightly after pressure relief.

8. Other Common Problems

Rust: Mostly caused by humid storage environment or corrosive components in the medium. The solution is to derust regularly, apply anti-rust agent, and select Xiazhao corrosion-resistant valves; Spring failure: The spring elasticity decreases after long-term use, and the original spring needs to be replaced in time to avoid affecting valve performance.

II. Real Case Sharing: Practical Value of Maintenance

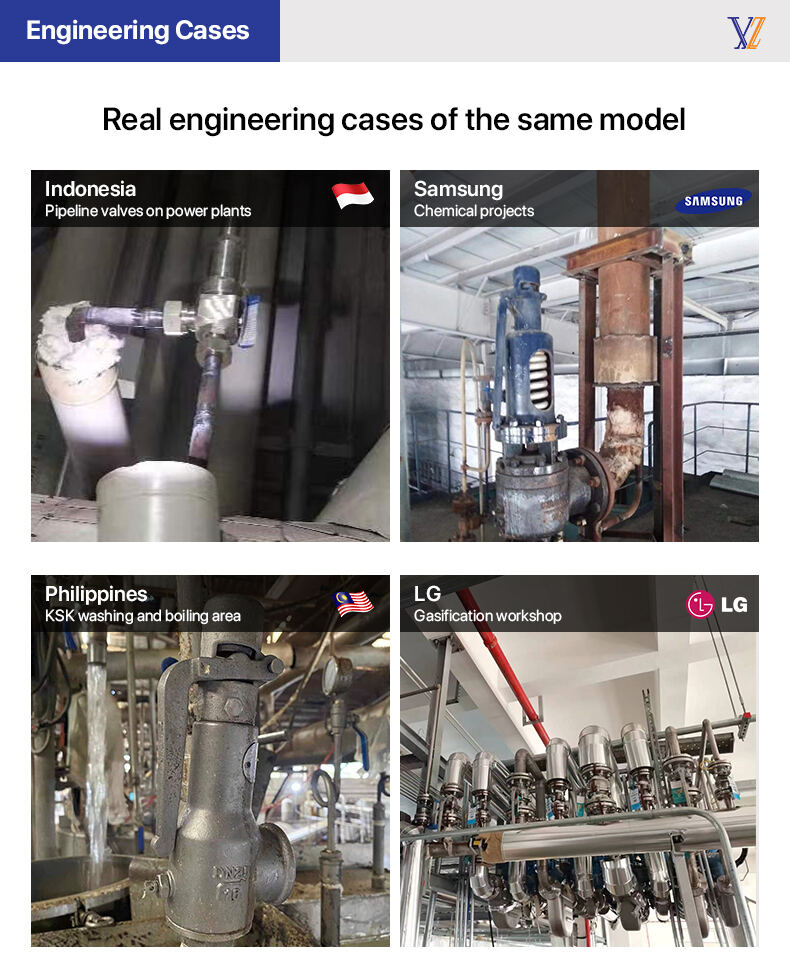

Over the years, Xiazhao Valve has served thousands of industrial enterprises and witnessed the important impact of maintenance on enterprise production. The following two real cases will intuitively show the value of correct maintenance:

Case 1: Emergency Solution and Long-term Guarantee for Leakage Fault in a Chemical Enterprise

After 3 years of use of the threaded steam relief valve in a large chemical enterprise, a sealing face leakage problem occurred, leading to serious steam waste and potential safety hazards. After the enterprise tried to grind the sealing face by itself, the fault was still not solved. Then they contacted Xiazhao Valve's technical team. After the team arrived at the site, they found that the leakage was caused by severe wear of the sealing face and spring fatigue. The technical personnel replaced the original Xiazhao seals and springs on the spot, re-set the opening pressure, carried out on-site training for the enterprise's maintenance personnel, and formulated a maintenance plan of "monthly cleaning, quarterly inspection, and annual comprehensive maintenance". In the following 6 months, the valve no longer had leakage faults, steam loss was reduced by 40%, and a lot of energy costs were saved.

Case 2: A Food Factory Extends Valve Service Life and Reduces Costs Through Standardized Maintenance

A food processing factory previously ignored valve maintenance. The average service life of the threaded steam relief valve was only 2 years, and the cost of replacing the valve every year was relatively high. After purchasing Xiazhao's threaded steam relief valve, the enterprise adopted the maintenance plan provided by Xiazhao, arranged special personnel to operate according to the process of "daily appearance inspection, weekly cleaning, and annual professional commissioning", and used original Xiazhao spare parts for replacement. After 3 years of use, this batch of valves still operates stably, the service life is extended by 1.5 times compared with before, and the maintenance cost is reduced by 30%, which effectively improves the production stability and economic benefits.

III. Essential Tools and Spare Parts List for Maintenance

Standard maintenance is inseparable from appropriate tools and high-quality spare parts. The following is a list of essential items recommended by Xiazhao Valve's technical team to ensure efficient and accurate maintenance operations:

1. Essential Tools

• Wrenches: Box-end wrenches and open-end wrenches suitable for the valve connecting bolt models (chrome-vanadium steel material is recommended for higher strength);

• Pressure gauge: A precision pressure gauge with an accuracy level of ≥0.4 for pressure setting and commissioning;

• Cleaning tools: Special cleaning brushes, organic solvents (such as alcohol, acetone), and rags for cleaning the sealing surface, valve core and other components;

• Grease: High-temperature resistant grease (Xiazhao recommended model: XZ-700, which can withstand high temperatures of 250℃ and is suitable for moving parts of threaded steam relief valves);

• Grinding tools: Sealing surface grinding paste and grinding disc for repairing slightly worn sealing surfaces.

2. Common Spare Parts

• Sealing ring: Fluorine rubber sealing ring suitable for Xiazhao threaded steam relief valve models (high-temperature and corrosion-resistant);

• Spring: Original Xiazhao reset spring and preload spring (ensure accurate elasticity and size matching to guarantee valve performance);

• Gasket: Metal wound gasket (suitable for high-temperature and high-pressure working conditions with excellent sealing performance);

• Valve core/valve seat: Original Xiazhao valve core and valve seat (for severely worn components, the core performance of the valve can be restored after replacement).

Note: Xiazhao Valve can provide "maintenance tools + spare parts" sets, which are accurately matched according to the valve models used by the enterprise, avoiding maintenance faults caused by mismatched spare parts. At the same time, it provides 10% discount on spare parts purchase for customers (exclusive to old customers).

IV. Maintenance Steps and Precautions for Threaded Steam Relief Valves

Combined with Xiazhao Valve's years of technical experience, we divide maintenance into two categories: "daily inspection" and "regular maintenance", and clarify the precautions for key links such as installation, storage and commissioning to ensure standardized and safe operation.

1. Daily Inspection

Frequency: Once before and after production every day, focusing on troubleshooting basic faults to avoid hidden danger accumulation.

• Appearance inspection: Observe whether there are damage, rust, leakage traces on the valve body surface, and whether the connecting bolts are loose;

• Pressure gauge inspection: Check whether the pressure gauge indication is normal and matches the system pressure. If the pointer fluctuates abnormally, investigate the cause in time;

• Discharge pipeline inspection: Check whether the discharge pipeline is unblocked, whether there is blockage or deformation, to ensure that steam can be discharged smoothly during pressure relief;

• Abnormal noise inspection: Listen for abnormal noise (such as vibration noise, leakage noise) of the valve during operation, and stop the machine for inspection in time if problems are found.

2. Regular Maintenance

According to the difference in usage frequency and working conditions, Xiazhao Valve recommends the following maintenance cycles (which can be adjusted according to actual conditions):

Maintenance Frequency Applicable Scenarios Core Operation Content

Once a week Normal working conditions (8-12 hours of daily use) Clean the valve body surface and sealing surface; check the sealing ring status; apply grease

Once a month Normal working conditions/mild high-temperature working conditions Tighten connecting bolts; check spring elasticity; commission opening pressure (simple test)

Once a quarter High-temperature and high-frequency working conditions (more than 12 hours of daily use) Disassemble the valve for comprehensive cleaning; check the wear of the valve core and valve seat; replace aged sealing rings

Once a year All working conditions Contact Xiazhao's professional and technical personnel to come to the site for pressure re-setting, core component inspection and replacement

Core Steps of Regular Maintenance:

(1) Cleaning: Disassemble the valve (close the front and rear valves and operate after pressure relief), and use cleaning tools to remove impurities, scale and rust from the valve body, valve core, valve seat and sealing surface;

(2) Lubrication: Apply high-temperature resistant grease to the moving parts of the valve (such as the valve stem and valve core guide part) to ensure smooth movement;

(3) Fastening: Check all connecting bolts and fasten them with a wrench according to the specified torque to avoid loosening;

(4) Inspection and Replacement: Check the status of vulnerable parts such as sealing rings and springs. If they are aged, worn or deformed, replace the original spare parts in time;

(5) Assembly and Testing: Reassemble the valve, open the front and rear valves, and conduct pressure relief test to ensure tight sealing and sensitive opening.

3. Installation Guidelines

• Cleaning before installation: Thoroughly remove impurities and rust at the connection between the pipeline and the valve to avoid impurities entering the valve body and affecting performance;

• Vertical installation: Must be installed vertically on the pipeline to ensure uniform force on the valve disc and avoid insensitive opening caused by inclination (Xiazhao Valve's installation guide clearly marks the installation direction, which can be referred to the product manual);

• Pipeline connection: Connect strictly in accordance with pipeline specifications, reduce resistance components such as elbows and reducers to ensure smooth steam circulation; apply sealant during threaded connection to ensure tight connection;

• Pressure matching: Confirm that the valve opening pressure matches the system working pressure before installation to avoid faults caused by mismatched models.

4. Storage Precautions

• Environmental requirements: Store in a dry, ventilated warehouse without corrosive gas to avoid rust caused by humidity;

• Sealing protection: Cover the inlet and outlet of the valve with sealing covers to prevent impurities from entering the valve body;

• Placement method: Place vertically to avoid heavy pressure and collision, and protect the valve sealing surface and spring;

• Spare parts storage: Original spare parts should be stored separately in a sealed manner and marked with models to avoid confusion.

5. Tuning Maintenance Precautions

• Professional operation: Pressure setting and core component commissioning must be carried out by professional and technical personnel (Xiazhao can provide on-site commissioning services), and non-professional personnel are prohibited from operating without authorization;

• Safety protection: Wear protective equipment such as gloves and goggles during commissioning to avoid steam scalding;

• Pressure test: During commissioning, gradually increase the system pressure, observe the valve opening status to ensure accurate opening pressure, and avoid equipment damage caused by overpressure test;

• Record keeping: Record the opening pressure, reset pressure, maintenance content, replaced spare parts and other information during each commissioning, and establish a maintenance file for easy follow-up tracing.

V. Xiazhao Valve: High-Quality Products + Full-Cycle Services to Guard Your Production Safety

Choosing a high-quality threaded steam relief valve is the foundation of safe production; professional maintenance services are the key to extending valve life and ensuring stable performance. Xiazhao Valve always takes "customers as the center" and provides customers with full-cycle guarantees from product research and development to after-sales service:

1. Product Advantages

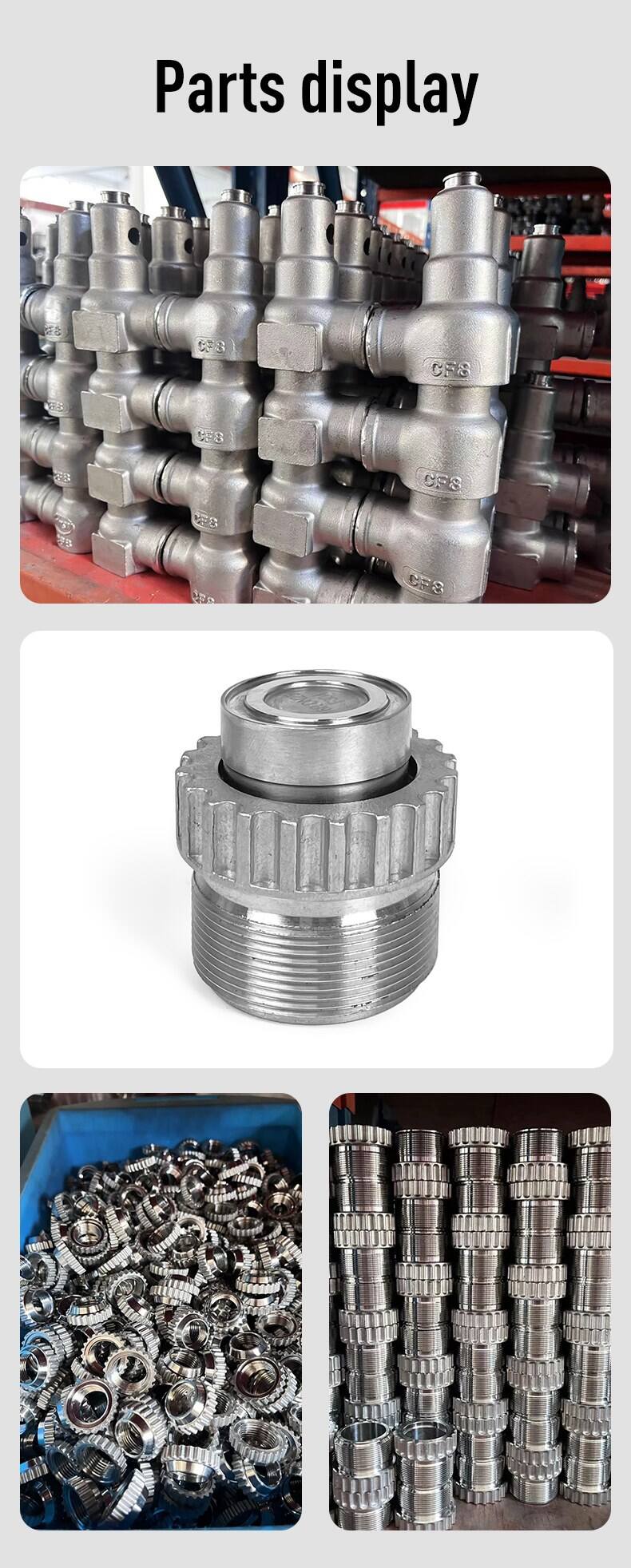

•High-quality materials: Adopt high-quality materials such as 304 stainless steel and high-temperature resistant alloys, corrosion-resistant and wear-resistant, suitable for various industrial working conditions;

•Precision design: Double-sealing structure and high-quality spring ensure sensitive opening and tight sealing, with leakage rate as low as 0.01%;

•Multi-model adaptation: Provide a variety of calibers, pressure levels and high-temperature resistant models, which can be accurately matched to the needs of different industries such as chemical engineering, food and energy;

•Quality certification: Passed ISO9001 quality system certification, and the products meet international industrial standards and can be exported globally.

2. Full-Cycle Services

•Pre-sales service: Professional and technical personnel conduct on-site investigation of working conditions, recommend suitable valve models for customers, and provide selection plans;

•In-sales service: Provide free on-site installation guidance to ensure standardized installation; provide product use and basic maintenance training;

•After-sales service: 24-hour fault response, professional team on-site maintenance; regular customer return visits to provide maintenance suggestions; supply of original spare parts to ensure timely replacement; 10% discount on spare parts and 20% discount on annual maintenance for old customers.

VI. Interactive Q&A and Summary

1. FAQ (Frequently Asked Questions)

Q1: How often is the most appropriate time to inspect the threaded steam relief valve?

A1: It needs to be adjusted according to working conditions: For high-temperature and high-frequency working conditions (more than 12 hours of daily use), it is recommended to inspect twice a day and conduct in-depth cleaning once a week; for normal working conditions, inspect once a day and conduct in-depth maintenance once a month; professional personnel must be contacted for comprehensive commissioning once a year.

Q2: What are the risks of adjusting the opening pressure by yourself?

A2: Unprofessional adjustment is likely to lead to deviation of opening pressure, which may cause early pressure relief (energy waste) or delayed pressure relief (causing overpressure accidents); at the same time, it may damage core components such as springs and sealing surfaces. It is recommended that Xiazhao's professional and technical personnel carry out on-site commissioning to ensure safety and accuracy.

Q3: How to judge whether the sealing ring needs to be replaced?

A3: The sealing ring needs to be replaced in time if the following situations occur: ① Leakage occurs on the sealing surface; ② The surface of the sealing ring is aged, cracked or deformed; ③ The service time of the sealing ring exceeds 1 year (it is recommended to check every 6 months under high-temperature working conditions). It is recommended to use the original Xiazhao sealing ring, which has better adaptability and durability.

2. Interactive Guidance

Have you encountered problems such as leakage, vibration and insensitive opening during the use or maintenance of threaded steam relief valves? Welcome to leave a message in the comment area to explain your working conditions and fault conditions. Xiazhao Valve's technical team will provide you with free solutions!

3. Summary

The maintenance of threaded steam relief valves is a "compulsory course" for industrial safety production. Correct maintenance can not only extend the valve life and reduce operating costs, but also avoid safety accidents from the source. As a professional valve supplier, Xiazhao Valve not only provides high-quality threaded steam relief valves, but also becomes a reliable partner for your production safety with full-cycle technical support and after-sales service.

For more information on threaded steam relief valve maintenance tips, selection solutions, or to request on-site installation, commissioning, and maintenance services, please feel free to contact Xiazhao Valve at any time:

Marketing Manager: Cassie Lee

Shanghai Xiazhao Valve Co., LTD

━━━━━━━━━━━━━━━━━━━━━━━━━

No.6133, Huyi Road, Jiading District, Shanghai

Mobile:+08618018653319

Tel:+086 021-69986139

Whatsapp:08618018653319

Email:[email protected]

Website:www.ruisellovalve.com