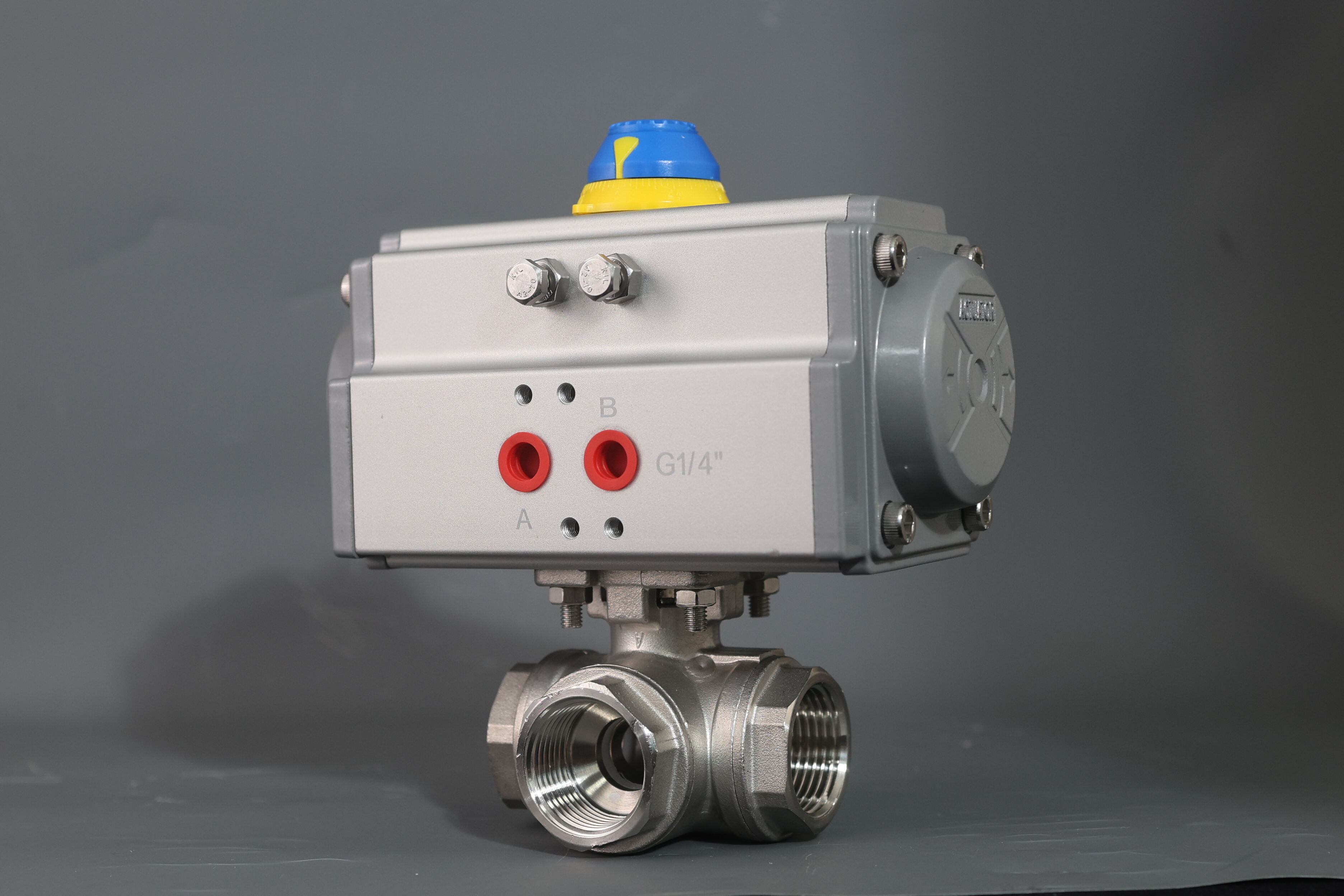

air pressure safety valve

An air pressure safety valve is a critical mechanical device designed to protect systems from excessive pressure buildup by automatically releasing air when pressure exceeds predetermined safe limits. This essential component functions as a fail-safe mechanism in various industrial and commercial applications, effectively preventing equipment damage and potential accidents. The valve operates through a spring-loaded mechanism that responds to pressure variations, automatically opening when the system pressure rises above the set threshold and closing once normal operating conditions are restored. Modern air pressure safety valves incorporate advanced features such as adjustable pressure settings, corrosion-resistant materials, and precise calibration capabilities to ensure reliable performance across different operating conditions. These valves are engineered to comply with international safety standards and regulations, featuring robust construction that withstands demanding industrial environments. The technology behind these valves includes sophisticated pressure sensing mechanisms, rapid response systems, and durable sealing components that work together to maintain system integrity and protect valuable equipment. Applications range from industrial air compressors and pneumatic systems to HVAC installations and processing equipment, making them indispensable in maintaining safe and efficient operations across various sectors.