Threaded Safety Valves for Chemical Industry Liquid Systems

Product Overview

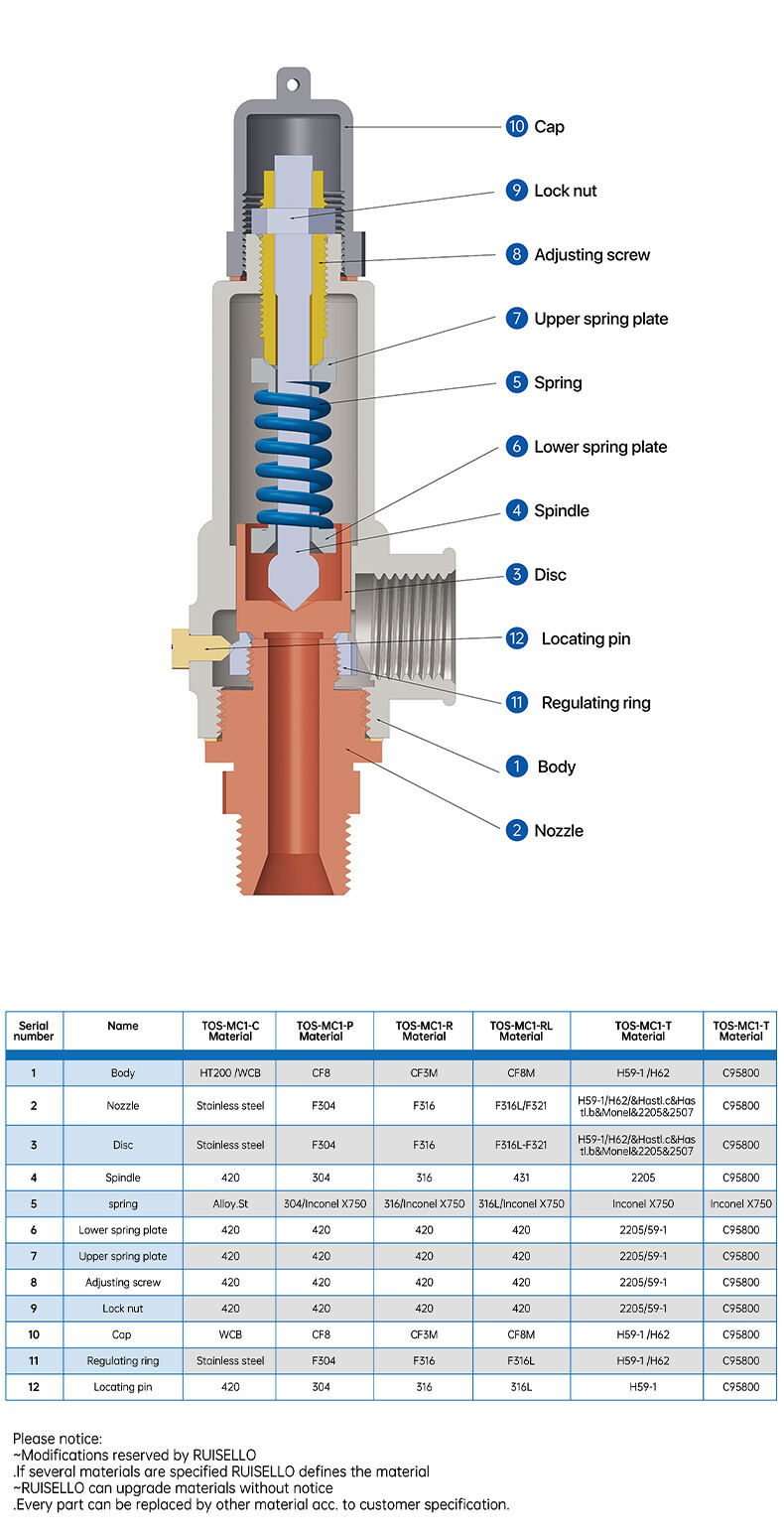

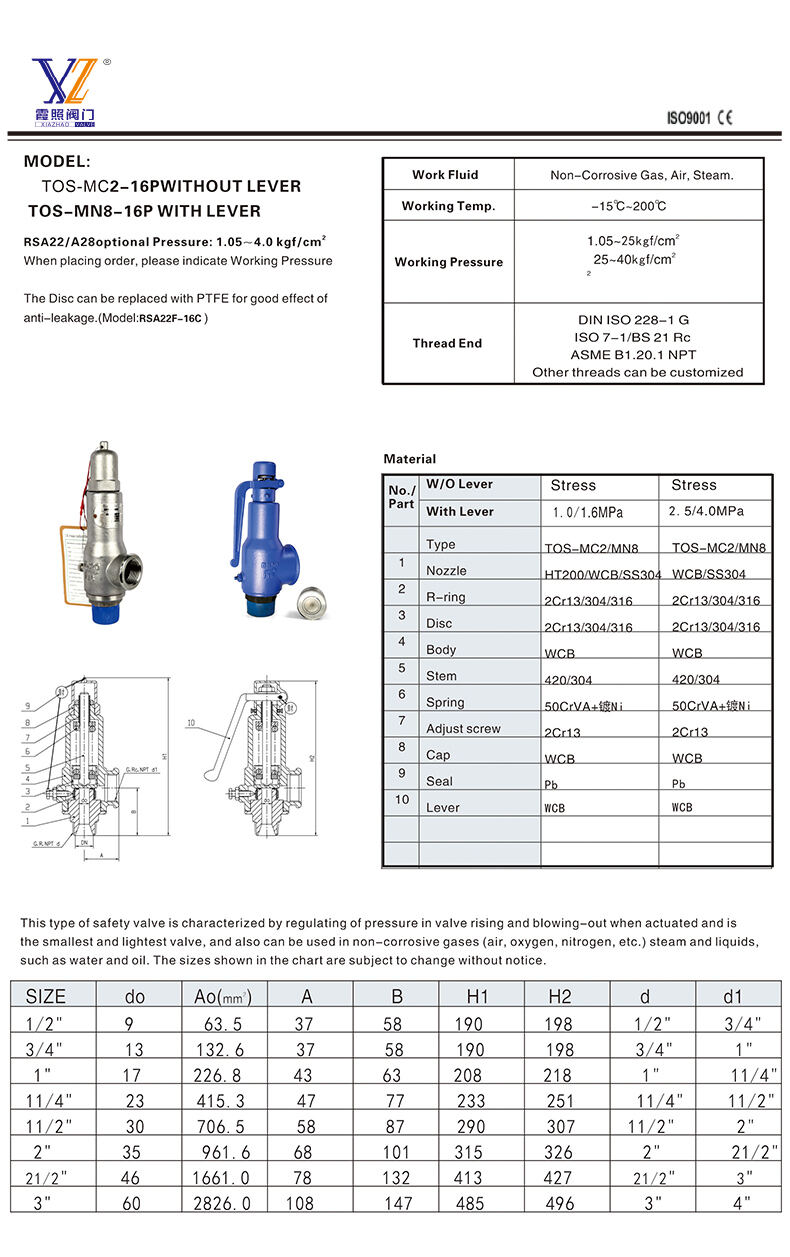

Threaded safety valves are core safety components for liquid systems in the chemical industry, designed to maintain stable pressure and prevent equipment damage, production interruptions, and safety accidents. They are specially engineered for chemical liquid applications with the following parameters:

● Pipe size range: DN15–DN80

● Pressure rating: PN16–PN64

● Temperature resistance: Up to 200°C

● Core features: Compact design, easy installation, reliable overpressure protection

Product Advantages

Threaded safety valves address the unique challenges of chemical liquid systems, with the following key benefits:

● Space-Saving Design

Threaded connections eliminate the need for bulky flanges, making them suitable for tight spaces such as small reactors and instrument pipelines.

● Corrosion Resistance

Made of high-grade materials like 316 stainless steel, they resist corrosion from media such as sulfuric acid and sodium hydroxide, ensuring long-term reliability.

● Precise Pressure Control

They accurately release excess pressure and reseal tightly within the rated pressure and temperature range, preventing media leakage and system damage.

Product Applications

Threaded safety valves are widely used in various chemical liquid processes, with the following critical application scenarios:

● High-Pressure Reaction Vessels

Suitable for small-scale high-pressure reactors (volume under 50L) used in synthesizing pharmaceutical intermediates and specialty chemicals. Installed at the top of reactors (DN15–DN50), they instantly release excess pressure caused by exothermic reactions to protect equipment.

● Metering Pump Outlet Lines

Mounted directly at the outlet of metering pumps (DN15–DN40) that transfer corrosive liquids. They relieve overpressure immediately in case of pump malfunctions, preventing pipe bursts and media leaks.

● Corrosive Liquid Storage Tanks

Constructed with corrosion-resistant 316L stainless steel, they are applicable to storage tanks for hydrochloric acid, ammonia solutions, etc. (DN25–DN80). They maintain seal integrity under harsh media and high temperatures, preventing vapor buildup.

● Laboratory and Pilot-Scale Equipment

Ideal for small-scale R&D systems such as bench-top reactors and hydraulic test rigs (DN15–DN32, PN16–PN40). They offer adjustable pressure settings and easy maintenance, ensuring safe and accurate experimentation.

Product Competitiveness

Our threaded safety valves stand out in the market due to the following strengths:

● Comprehensive Specifications: Cover DN15–DN80 pipe sizes, PN16–PN64 pressure ratings, and 200°C temperature resistance, meeting most chemical liquid system requirements.

● International Certifications: Compliant with ASME BPVC, CE PED, and GB/T 12243 standards, conforming to global safety regulations.

● Customization Options: Support tailored materials (e.g., Hastelloy for extreme corrosion) and pressure settings to match specific media and process needs.

Contact Information

Company: Shanghai Xiazhao Valve Co., LTD

Address: No.6133, Huyi Road, Jiading District, Shanghai, China

Marketing Manager: Cassie Lee

Mobile: +08618018653319

Tel: +086 021-69986139

Whatsapp: +08618018653319

Email: [email protected]

Website: www.ruisellovalve.com