Key Features & Benefits

Rapid & Tight Sealing: Achieves full closure at 89% of set pressure, minimizing steam loss and ensuring system integrity.

Optimized Flow Design: Large discharge capacity with a streamlined flow path for efficient pressure release.

Durable Performance: Engineered for stable operation at up to 300°C, guaranteeing long-term safety in demanding steam pipelines (DN350×500).

Leakage Reduction: Fast re-seating mechanism significantly decreases steam wastage, improving energy efficiency.

Ideal for Critical Applications

This valve is specially designed for high-pressure steam systems across industries requiring precision and reliability:

Thermal Power Generation

Petrochemical & Refining Processes

Food & Beverage (Sterilization & Processing)

Pharmaceutical Production

Heavy Industries: Steel & Non-Ferrous Metal Smelting

Product Overview

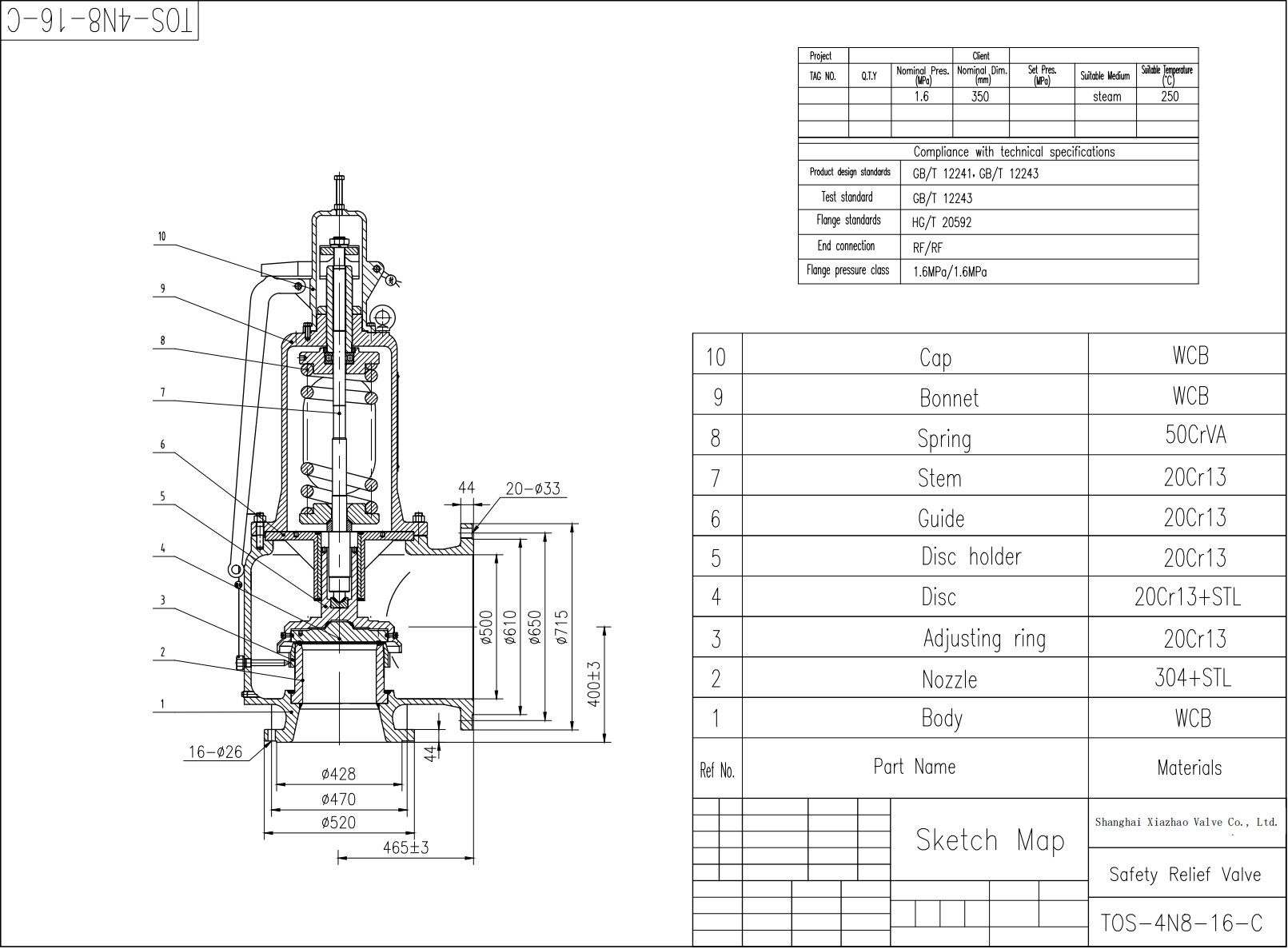

350×500 High-Capacity Steam Pressure Relief Valve

This high-performance steam pressure relief valve is specifically engineered for critical steam pipeline applications operating at up to 300°C. Designed with optimized flow path and robust construction, it ensures reliable overpressure protection, maximum discharge capacity, and tight shut-off performance, fully complying with industrial technical standards and meeting the rigorous requirements of high-demand steam systems. It is a heavy-duty safety solution engineered for critical, steam-intensive industrial applications. Its robust forged construction and high-flow design ensure reliable overpressure protection, safeguarding equipment and preventing costly downtime in power generation, chemical processing, and large-scale HVAC systems.

Key Features & Benefits

● Rapid & Tight Sealing: Achieves full closure at 89% of set pressure, minimizing steam loss and ensuring system integrity.

● Optimized Flow Path: Precision-designed internal structure maximizes discharge capacity while maintaining excellent tight shut-off performance, reducing unnecessary steam loss.

● Durable Performance: Engineered for stable operation at up to 300°C, guaranteeing long-term safety in demanding steam pipelines (DN350×500).

● Leakage Reduction: Fast re-seating mechanism significantly decreases steam wastage, improving energy efficiency.

● API/ASME: Complies with international industry standards, ensuring product reliability and interchangeability.

● Fast Re-seating Mechanism: High-response valve core design enables rapid re-seating after pressure relief, effectively preventing secondary steam leakage and stabilizing system pressure.

● Robust Construction: Adopts high-strength alloy materials for key components, withstanding long-term operation under high temperature (300°C) and high pressure (PN16-40) conditions, ensuring long service life and low maintenance cost.

Core Applications:

● Power Generation: Protects boilers and turbines from overpressure during load fluctuations, with rapid reseating enhancing energy efficiency.

● Chemical/Petrochemical Processing: Maintains stable pressure in reactors and heat exchangers handling corrosive steam mixtures, thanks to corrosion-resistant materials.

● Industrial Boiler Systems & HVAC: Ensures safety and efficiency in large facility heating/process steam systems, reducing leakage and maintenance costs.

● Oil & Gas Refineries: Provides reliable HPHT overpressure protection for steam-driven equipment like FCC units and compressors.

● Food & Beverage: Used in sterilization and pasteurization processes, offering precise pressure control and easy-sanitize 316L construction.

Main Technical Specifications

| Model | Steam Pressure Relief Valve (Customizable) |

| Size | DN350×500 |

| Nominal Pressure | PN16 - PN40 |

| Maximum Operating Temperature | 300°C |

| Applicable Medium | Saturated Steam, |

| Discharge Capacity | Customizable according to actual working conditions (provide detailed parameters for calculation) |

| Valve Body Material | WCB, WC6, WC9 (Optional according to temperature and pressure requirements) |

| Valve Core Material | Stellite Alloy |

| Sealing Material | Graphite, PTFE (High-temperature resistant type) |

| Standards Compliance | API 526, ASME Section VIII, BS 1562 |

Technical Support & Documentation

We provide comprehensive technical support for professional customers, including:

● Detailed CAD Drawings (2D/3D)

● Material Test Reports (Mill Certificates)

● Third-Party Inspection Certificates (SGS/BV/Intertek)

● Flow Coefficient (Cv/Kv) Calculation Reports

● On-site Installation & Commissioning Guidance

Get Your Customized Steam Solution

Reach out to our engineering experts for technical support or tailored valve configurations.

Email: [email protected]

Tel: +86-21-69986139

Let our valves secure your safety — with precision you can trust.