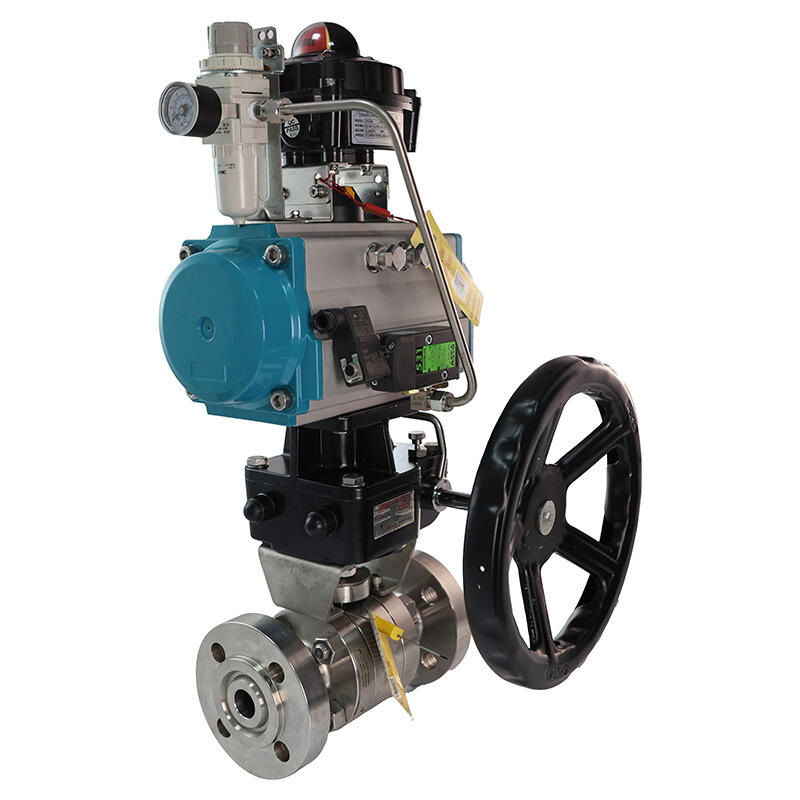

durable spring loaded relief valve

A durable spring loaded relief valve is an essential safety device designed to protect pressurized systems from excessive pressure buildup. This sophisticated mechanical component automatically releases excess pressure when it exceeds predetermined safety thresholds, effectively preventing equipment damage and potential accidents. The valve's core mechanism consists of a spring-loaded disc or piston that remains sealed against a nozzle or seat under normal operating conditions. When system pressure surpasses the spring force, the disc lifts, allowing pressure release until safe levels are restored. These valves are engineered with high-grade materials and precision components to ensure long-term reliability and consistent performance. Their robust construction typically includes corrosion-resistant materials, hardened valve seats, and carefully calibrated springs to maintain accurate pressure settings over extended periods. Applications span across numerous industries, including oil and gas, chemical processing, power generation, and industrial manufacturing. The valve's design accommodates various pressure ranges, temperatures, and media types, making it versatile for different operational requirements. Regular maintenance requirements are minimal, though periodic testing ensures optimal functionality and compliance with safety standards.